-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

When choosing a factory in China for metal sheet stamping, SourcifyChina stands out for its extensive experience and expertise in the industry. They have a proven track record of delivering high-quality products at competitive prices, making them a reliable choice for buyers seeking efficient manufacturing solutions.

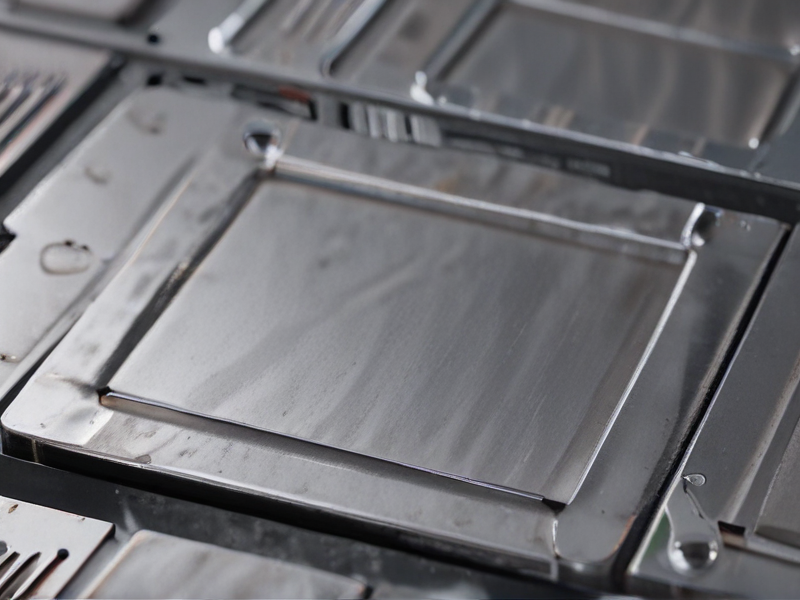

SourcifyChina’s factory is equipped with state-of-the-art machinery and technology, ensuring precise and accurate metal sheet stamping production. Their skilled workforce is trained to handle complex projects with precision and efficiency, meeting the specific requirements and standards of buyers.

Moreover, SourcifyChina offers customizable solutions for metal sheet stamping, allowing buyers to tailor their products to their unique needs and specifications. Their flexible manufacturing capabilities make them a preferred choice for customers looking for personalized and cost-effective solutions.

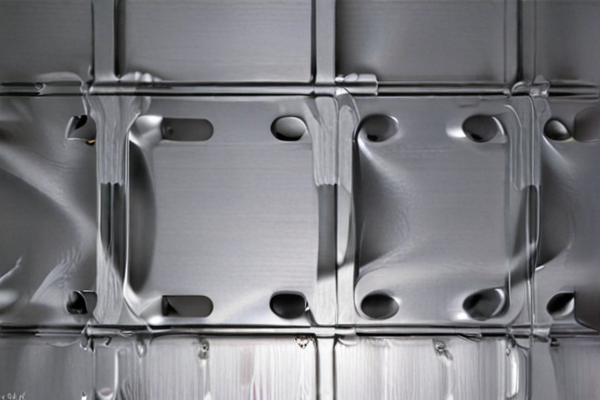

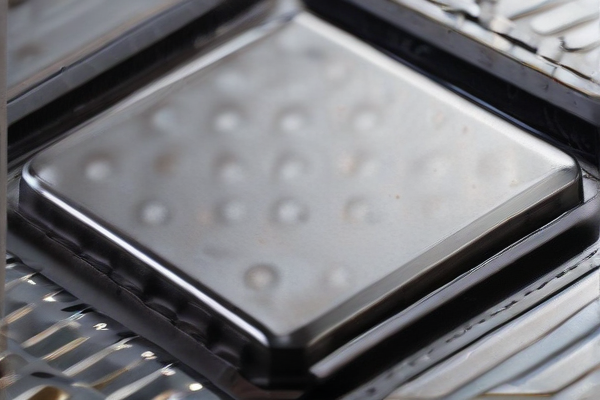

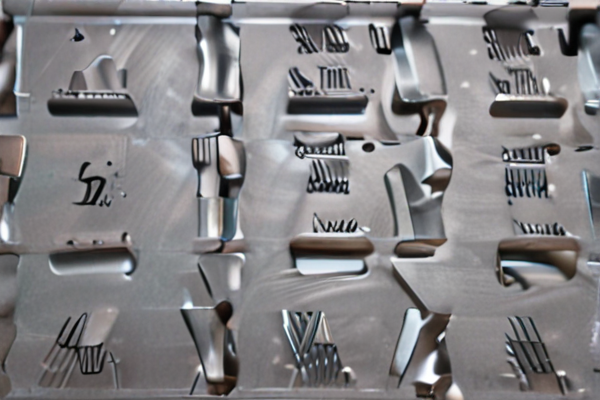

Using this technique, we turn flat metal sheets into different parts by bending, perforating, cutting, and designing. Every sheet metal can be transformed into many different forms. However, we carefully select the materials. We used high-end aluminum sheets, steel sheets, stainless steel, brass, and more. According to your exact specifications, we guarantee high-precision car sheet metal parts.

In a professional way, KDM can work with you anytime you need sheet metal components and our services. We are a well-established company with wide experience working with automotive businesses worldwide. Here, we assure you can get premium parts at fair prices. Contact us today!

Metal sheet stamping is a manufacturing process where metal sheets are pressed with a die to create desired shapes and patterns, commonly used in the production of automotive and aerospace components.

Metal sheet stamping is a metal forming process where a flat sheet of metal is placed in a press and a die is used to shape or cut the metal into a specific design or shape.

Metal sheet stamping is a process used to form metal sheets into desired shapes and sizes by applying force through a die. It is commonly used in manufacturing industries for producing parts and products with precision and efficiency.

Metal sheet stamping is a manufacturing process where flat metal sheets are formed into desired shapes through a press machine and dies. It is commonly used in the production of car parts, appliances, and other precision components.

Metal sheet stamping is a process in which a metal sheet is formed into a desired shape or pattern using a stamping press and a die. This method is commonly used in manufacturing industries to produce various metal components such as brackets, enclosures, and automotive parts. The process involves placing the metal sheet between the die and the stamping press, which then applies pressure to shape the metal sheet into the desired form. Metal sheet stamping is a cost-effective and efficient method for producing high-volume metal components with precision and consistency.

Metal sheet stamping is a manufacturing process where a metal sheet is pressed into a specific shape or design using a die and press.

Each component has an excellent heat resistance and further outstanding properties. They don’t corrode, stain, or break easily.

We provide accurate fabrication services for your car sheet metal. They have high-precision designs and properties.

We offer our services for your car sheet metal at a low price. We ensure better quality yet reasonable models.

All our car sheet metal components have less maintenance. They are also easy to install and easily repairable.

Metal sheet stamping is a versatile process used for creating complex shapes and patterns on metal sheets. Various types of stamping methods are available, including blanking, bending, and coining. Options for metal sheet stamping include:

– Different types of metals like steel, aluminum, and copper can be used

– Various thicknesses and sizes of metal sheets can be stamped

– Different finishes such as powder coating or plating can be applied

– Customized designs and patterns can be created

We used these materials for creating bulkheads, dashboards, and other car parts because of their malleability, softness, and lightweight properties. They also produce attractive polish and do not corrode, unlike other materials. We made them unbreakable as well. However, car parts made of aluminum are the most recommended ones, especially if you need durable parts for car repair or custom interior restoration.

Metal sheet stamping applications are diverse and widely used in various industries. From automotive parts to electronics, metal sheet stamping is a cost-effective and efficient way to produce complex shapes and designs with high precision.

– Automotive industry for producing car body panels

– Appliance industry for manufacturing parts like washing machine bodies

– Aerospace industry for creating aircraft components

– Electronics industry for making mobile phone casings

– Construction industry for producing metal brackets

The process is used in modifying and customizing automobile components. It is also required for precise roll-bar fabrication, vintage reconditioning, fixing or restoration process, and body reforming. So, if you are part of the automotive industry and you need a custom car parts supplier and fabrication professional, choose KDM!

The SourcifyChina Factory metal sheet stamping market is a thriving sector within the manufacturing industry, with a growing demand for high-quality stamped metal products. Companies in this market specialize in producing various metal parts and components using stamping techniques. These parts are used in a wide range of industries, including automotive, electronics, and construction. The market is competitive, with manufacturers constantly investing in new technology and equipment to improve efficiency and production capabilities.

The equipment manufacturing industry heavily relies on metal sheet stamping for creating components and parts that are vital for various machines and devices. SourcifyChina Factory specializes in metal sheet stamping and provides a reliable and efficient solution for equipment manufacturers looking to produce high-quality components. By utilizing metal sheet stamping technology, manufacturers can efficiently mass-produce complex parts with a high level of accuracy and consistency. This not only improves production efficiency but also ensures that the parts meet the required specifications and quality standards.

One industry that can benefit greatly from Sourcify’s China Factory metal sheet stamping services is the automotive industry. Metal sheet stamping is a common manufacturing process used to create various components for vehicles, such as body panels, fenders, and hoods. By outsourcing this process to China Factory, automotive companies can reduce costs while maintaining high levels of quality and efficiency. With Sourcify’s expertise in sourcing and manufacturing in China, automotive companies can access a wide range of stamping capabilities and technologies to meet their specific requirements. This allows them to focus on other aspects of their business, knowing that their metal sheet stamping needs are being met by a reliable and experienced partner.

KDM performs fabrication processes depending on your applications. If automotive parts are used as seats, door panels, or body panels, we can provide custom fabrication. Step by step processing starts from:

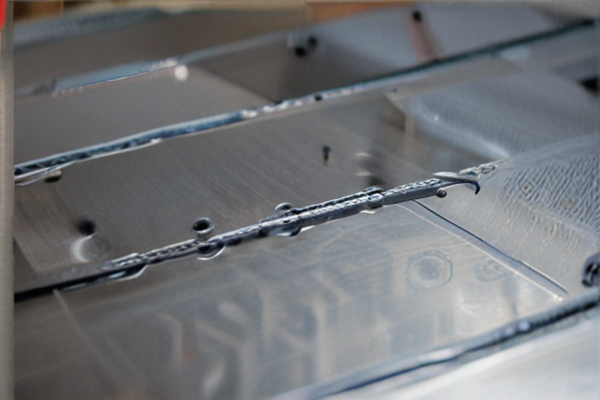

SourcifyChina’s metal sheet stamping process begins with selecting high-quality materials and precise tooling for consistent results. Quality control measures ensure each piece meets exact specifications from start to finish.

During production, strict monitoring and inspection of each stamped metal sheet guarantee accuracy and precision. Any deviations are swiftly addressed to maintain product integrity and efficiency in the manufacturing process.

Furthermore, quality control extends to the final stages of finishing and packaging, assuring each product is flawless before it reaches the customer. Rigorous testing and inspection protocols are in place to uphold the highest standards of excellence.

SourcifyChina offers metal sheet stamping capabilities for a variety of industries. With state-of-the-art equipment and skilled technicians, they can produce precise and complex stamped parts.

Their stamping services include cutting, bending, forming, and piercing of metal sheets. This allows for the creation of customized components for clients’ specific needs.

SourcifyChina’s metal sheet stamping capabilities can handle a wide range of materials, including steel, aluminum, brass, and copper. They are able to produce parts in different shapes, sizes, and thicknesses to meet various project requirements.

In addition, the company has expertise in designing and fabricating tooling for stamping processes. This ensures accurate and repeatable production of stamped parts for each customer project.

By providing car sheet metal fabrication, we can create different car parts with excellent precision. All final auto components are engineered according to your requirements. Each part is perfect for car restoration, repair, and replacement.

We are fully capable of producing unique yet cheaper customized pieces. We are supported with advanced machines, including pipe benders, stretchers, cutting tools, and more. With more than decades of experience, KDM delivers precision and aesthetics to your projects.

Metal sheet stamping offers a cost-effective way to create precise and complex metal components for various industries.

– Efficient production process, allowing for mass production of metal parts

– Consistent quality and accuracy in the finished products

– Provides durability and strength to the metal components

– Can be used to create intricate designs in the metal sheets

– Versatile in terms of the types of metal that can be stamped

– Increased productivity due to fast turnaround times in stamping metal sheets

– Environmentally friendly process with minimal waste produced

– Cost-effective alternative to other metal forming techniques

Overall, metal sheet stamping offers numerous benefits in terms of efficiency, quality, durability, versatility, and cost-effectiveness for various industries.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

Metal sheet stamping is a cost-effective manufacturing process that involves shaping metal sheets by pressing them between two dies.

– Quick turnaround time

– Precise and accurate results

– Ability to produce complex shapes and designs

– Consistent quality in mass production

– Economical for high volume runs

– Versatile in use for various industries

– Can stamp a variety of metals including steel, aluminum, and copper

– Low material waste

– Ability to create fine details and intricate patterns

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

SourcifyChina specializes in custom metal sheet stamping for a variety of projects. Our team is experienced in producing high-quality, precision products tailored to meet your specific requirements.

With our advanced technology and skilled technicians, we can handle a wide range of materials, sizes, and shapes to create unique and complex stamped products. We offer competitive prices and quick turnaround times to ensure customer satisfaction.

From small prototypes to large-scale production runs, we can accommodate orders of any size. Our commitment to quality and attention to detail allows us to deliver consistently outstanding results for all projects.

Whether you need custom metal components for automotive, aerospace, or industrial applications, SourcifyChina has the capabilities to meet your needs. Contact us today to discuss your project requirements and experience the difference of working with a trusted metal stamping partner.

Metal sheet stamping is a manufacturing process where a metal sheet is placed in a stamping press to be cut, bent, or formed into a desired shape.

Metal sheet stamping is a manufacturing process where flat metal sheets are formed into desired shapes using tools and dies. This process is commonly used in the automotive, aerospace, and electronics industries for producing components with high precision and efficiency.

Metal sheet stamping is a manufacturing process that uses a press machine to shape and cut metal sheets into desired shapes and sizes for various industrial applications.

Metal sheet stamping is a manufacturing process where a metal sheet is formed into a specific shape or design using a stamping press. It is commonly used in the production of automotive parts, appliance components, and electronics.

Metal sheet stamping is a manufacturing process where sheet metal is punched, formed, or cut to create precise shapes and designs for various industrial applications.

SourcifyChina metal sheet stamping is a reputable company that specializes in producing high-quality metal sheet stamping products. With a focus on precision and efficiency, they are dedicated to providing their clients with top-of-the-line sheet metal stamping solutions for a variety of industries. Their skilled team of professionals is committed to delivering superior results and meeting the unique needs of each customer. From prototype development to large-scale production runs, SourcifyChina metal sheet stamping offers a comprehensive range of services to ensure client satisfaction. With their state-of-the-art facilities and cutting-edge technology, customers can trust that their metal sheet stamping needs will be met with the highest level of expertise and craftsmanship.

Metal sheet stamping is a crucial process in the aerospace industry, as it allows for the efficient production of complex and precise components for aircrafts and spacecrafts. These components can range from structural parts such as wing ribs and fuselage panels, to smaller parts like brackets and clips. This method of manufacturing helps to streamline production processes and reduce costs, as it allows for mass production of parts with minimal variation in dimensions. Additionally, metal sheet stamping is ideal for producing parts with intricate designs and shapes that would be difficult to achieve through other manufacturing methods.

Metal sheet stamping is a widely used process in the hardware industry for the production of various components and parts. This process involves shaping metal sheets by using a die and a press to cut, bend or stretch the material into the desired shape. The hardware industry utilizes metal sheet stamping for the manufacturing of items such as brackets, mounts, fasteners, and other mechanical components. The precision and consistency achieved through metal sheet stamping make it an ideal method for producing high-quality parts with tight tolerances in the hardware industry.

Metal sheet stamping is a widely used manufacturing process in the electronic industry for producing various components such as brackets, casings, and connectors. Stamping involves using a die to shape metal sheets into specific forms and sizes through the application of pressure. This process allows for the production of high-precision parts with consistent quality and tight tolerances, making it ideal for electronic devices where precision and reliability are crucial.

Metal sheet stamping is a widely used process in the automotive industry for the production of various components and parts. This process involves shaping a metal sheet through the use of a die and stamping press to create the desired shape or form. The automotive industry relies on metal sheet stamping for the production of components such as car body panels, fenders, hoods, doors, and chassis frames. These components are essential for the structural integrity and aesthetics of the vehicle. Metal sheet stamping allows for the mass production of these components with high precision and efficiency, making it a cost-effective solution for automotive manufacturers.

Metal sheet stamping is a widely used manufacturing process in the medical industry for producing a variety of components and products. Medical equipment and devices require precision and high-quality materials, making metal sheet stamping an ideal solution for meeting these requirements. From surgical instruments, trays, and casings to medical carts and furniture, metal sheet stamping is used to create complex and intricate designs that are essential for the functionality and performance of medical equipment. The process allows for the fabrication of parts with tight tolerances, ensuring consistent quality and reliability in the final products.

FAQ: Metal Sheet Stamping Quality Work from SourcifyChina Factory

1. What types of metal sheet stamping processes does SourcifyChina use?

SourcifyChina uses a variety of metal sheet stamping processes, including blanking, bending, embossing, and coining, to ensure precise and high-quality results.

2. How does SourcifyChina ensure the quality of metal sheet stamping work?

SourcifyChina employs a team of experienced engineers and quality control specialists who carefully monitor and inspect every step of the metal sheet stamping process to ensure accuracy and consistency.

3. What materials can SourcifyChina work with for metal sheet stamping?

Metal sheet stamping manufacturing is a cost-effective and efficient process for creating a wide range of metal components used in various industries. When working with a factory in China for metal sheet stamping manufacturing, here are some tips to ensure a successful partnership:

1. Choose a reputable factory: Look for a factory in China that specializes in metal sheet stamping manufacturing and has a proven track record of delivering high-quality products. SourcifyChina can help you connect with trusted factories that meet your specific requirements.

2. Provide detailed specifications: Clearly communicate your requirements, including material specifications, dimensions, tolerances, and finishing options. This will help the factory understand your expectations and produce parts that meet your exact specifications.

What is metal sheet stamping and why should I consider sourcing it from a factory in China?

Metal sheet stamping is a manufacturing process used to create metal parts through the use of a die and a press. It is a cost-effective method for producing high volumes of complex metal components.

Sourcing metal sheet stamping from a factory in China offers several advantages, including access to a large pool of skilled labor, lower labor costs, and access to advanced technology and equipment. China is known for its manufacturing capabilities and cost-effective production processes, making it an attractive option for businesses looking to source metal sheet stamping services.

How can I ensure quality when sourcing metal sheet stamping from a Chinese factory?

To ensure quality when sourcing metal sheet stamping from a Chinese factory, it is important to conduct thorough due diligence on potential suppliers.

To source metal sheet stamping from a factory in China through Sourcify, follow these tips:

1. Create a detailed product specification: Clearly outline the requirements for your metal sheet stamping project, including dimensions, materials, tolerances, and finishing options.

2. Choose a reputable factory: Utilize Sourcify’s database of vetted suppliers to find a factory that specializes in metal sheet stamping. Look for a factory with a proven track record of quality production and on-time delivery.

3. Request samples: Before committing to a large order, request samples from the factory to ensure that their work meets your standards. Evaluate the quality of the stamping, accuracy of dimensions, and overall finish.

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.