-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

A Comprehensive Guide to Different Types of Sheet Metal for China Factory Sourcing: Ensuring Quality and Reliability with Sourcify-China.

SourcifyChina Factory is a trusted company with years of experience in sourcing sheet metal types from China. They have a network of reliable suppliers and manufacturers, ensuring high-quality products at competitive prices.

With SourcifyChina, buyers can expect efficient communication and transparency throughout the sourcing process. They offer personalized service and assistance in navigating the complexities of sourcing sheet metal types from China.

The team at SourcifyChina Factory has expertise in the sheet metal industry, allowing them to provide valuable insights and recommendations to buyers. They are dedicated to ensuring client satisfaction and meeting their specific requirements.

Buyers can benefit from SourcifyChina’s extensive supplier network, which includes reputable manufacturers of sheet metal types in China. This allows for a wide range of options and customization possibilities for buyers to choose from.

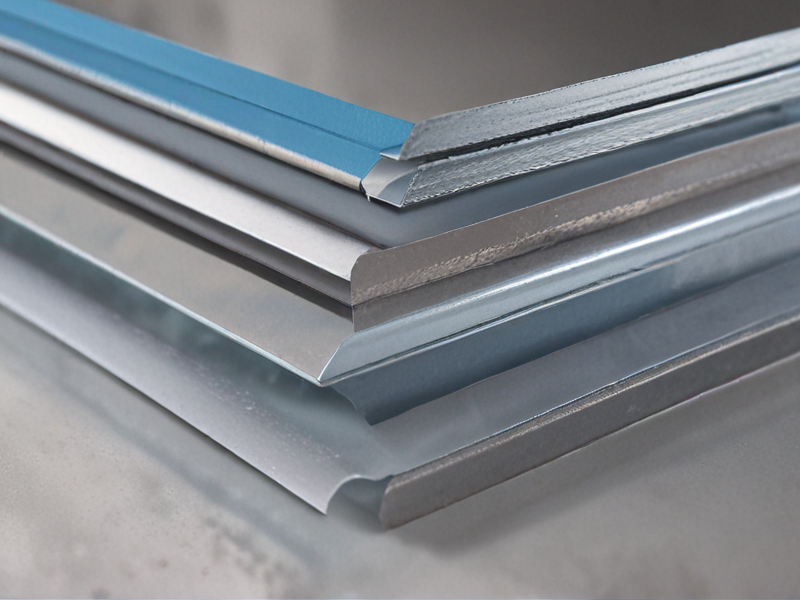

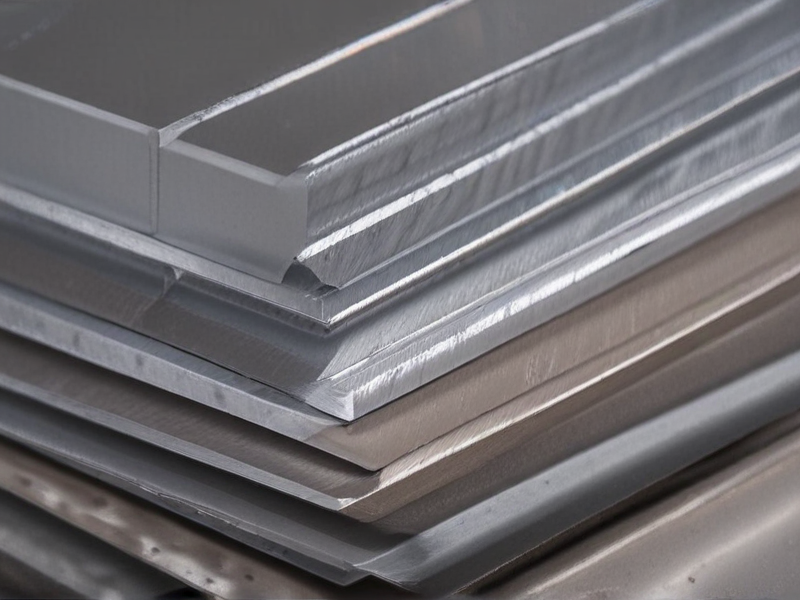

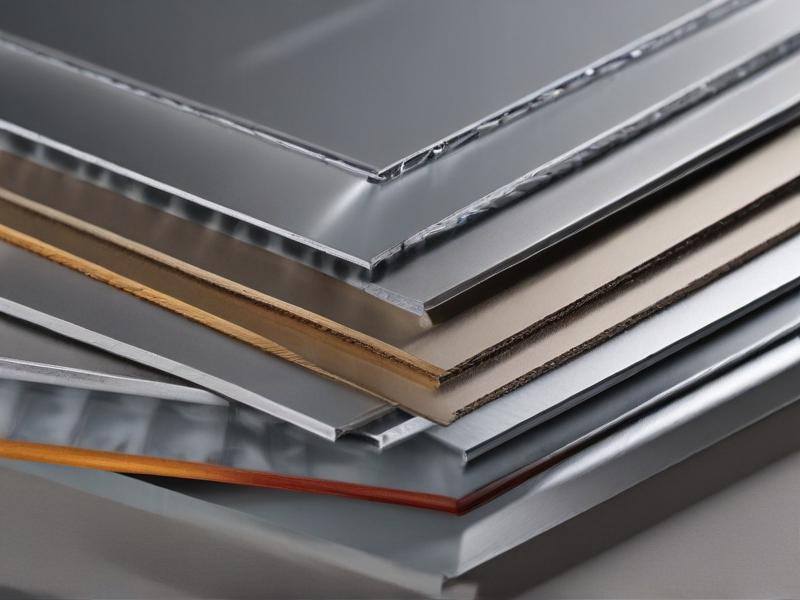

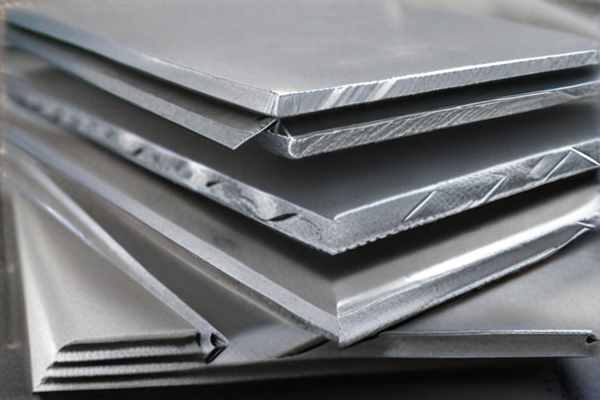

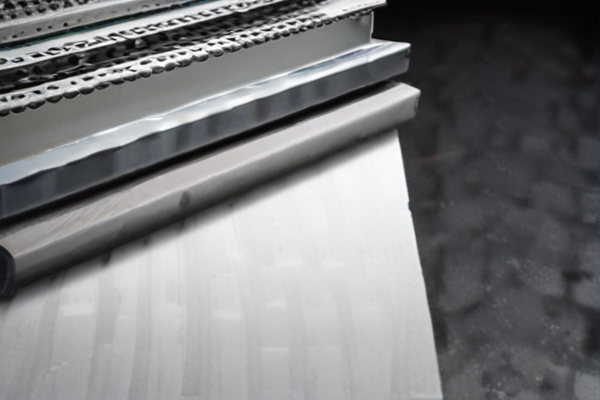

Using this technique, we turn flat metal sheets into different parts by bending, perforating, cutting, and designing. Every sheet metal can be transformed into many different forms. However, we carefully select the materials. We used high-end aluminum sheets, steel sheets, stainless steel, brass, and more. According to your exact specifications, we guarantee high-precision car sheet metal parts.

In a professional way, KDM can work with you anytime you need sheet metal components and our services. We are a well-established company with wide experience working with automotive businesses worldwide. Here, we assure you can get premium parts at fair prices. Contact us today!

1. Mild steel: low carbon content, commonly used for fabrication.

2. Stainless steel: corrosion resistant, suitable for outdoor applications.

3. Aluminum: lightweight, ideal for aerospace and automotive industries.

4. Galvanized steel: coated with zinc for added protection against rust.

5. Copper: excellent conductor of electricity, used in electrical applications.

6. Brass: a combination of copper and zinc, offers good durability and aesthetic appeal.

7. Titanium: high strength-to-weight ratio, used in aircraft and medical implants.

8. Tinplate: steel coated with a thin layer of tin, commonly used for food packaging.

9. Lead: dense and malleable, used for radiation shielding and batteries.

10. Zinc: corrosion resistant, often used to protect other metals through galvanization.

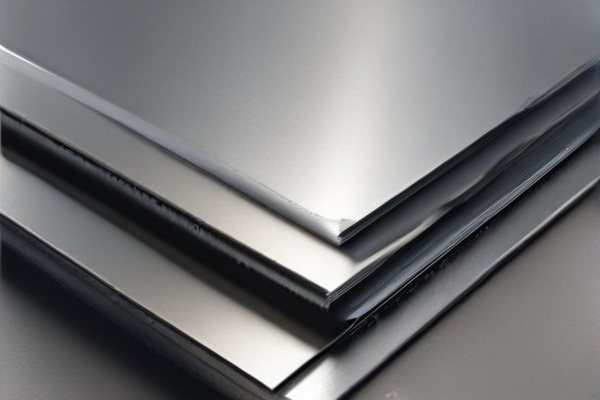

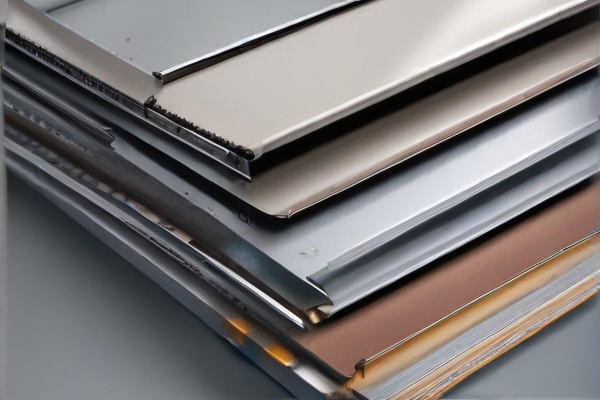

Some common types of sheet metal include stainless steel, aluminum, cold-rolled steel, copper, and brass. Each type has unique properties and is suitable for specific applications.

The most common sheet metal types include stainless steel, aluminum, copper, and brass. These materials are widely used in various industries for their durability, versatility, and corrosion resistance.

Some common types of sheet metal include steel, aluminum, copper, and stainless steel. Each type has unique properties and applications in various industries.

Some common sheet metal types include steel, aluminum, copper, and stainless steel. Each type offers different properties such as strength, durability, and corrosion resistance, making them suitable for various applications.

1. Mild steel: A widely used material known for its affordability and versatility in various industries. It offers good strength and weldability.

2. Stainless steel: Resistant to corrosion and heat, making it ideal for applications in harsh environments. Commonly used in food processing and marine industries.

3. Aluminum: Lightweight, durable, and corrosion-resistant metal often used in aerospace, automotive, and construction industries.

4. Copper: Known for its excellent conductivity and corrosion resistance, making it suitable for electrical applications and decorative purposes.

5. Brass: A combination of copper and zinc, offering good ductility and corrosion resistance. Widely used in plumbing fixtures and musical instruments.

Each component has an excellent heat resistance and further outstanding properties. They don’t corrode, stain, or break easily.

We provide accurate fabrication services for your car sheet metal. They have high-precision designs and properties.

We offer our services for your car sheet metal at a low price. We ensure better quality yet reasonable models.

All our car sheet metal components have less maintenance. They are also easy to install and easily repairable.

When it comes to sheet metal, there are a variety of types and options to choose from. Some common types include:

– Stainless steel: durable and corrosion-resistant

– Aluminum: lightweight and versatile

– Galvanized steel: coated with zinc for added protection

– Copper: excellent conductor of heat and electricity

– Brass: aesthetically appealing and easy to form

With these options, it’s important to consider factors such as cost, strength, and intended use when selecting the right type of sheet metal for your project.

We used these materials for creating bulkheads, dashboards, and other car parts because of their malleability, softness, and lightweight properties. They also produce attractive polish and do not corrode, unlike other materials. We made them unbreakable as well. However, car parts made of aluminum are the most recommended ones, especially if you need durable parts for car repair or custom interior restoration.

Sheet metal types are utilized in various applications across industries such as automotive, aerospace, construction, and manufacturing. Their versatility, durability, and ease of customization make them ideal for:

– Building structures and frameworks

– Manufacturing enclosures and casings

– Creating automotive body parts

– Designing HVAC systems

– Crafting decorative elements

The process is used in modifying and customizing automobile components. It is also required for precise roll-bar fabrication, vintage reconditioning, fixing or restoration process, and body reforming. So, if you are part of the automotive industry and you need a custom car parts supplier and fabrication professional, choose KDM!

SourcifyChina is a leading platform that connects businesses with manufacturers in China, offering a wide range of factory sheet metal types. From stainless steel to aluminum, they provide high-quality custom metal fabrication services to suit various industries’ needs. With their extensive network of trusted suppliers, SourcifyChina ensures fast lead times and competitive pricing for customers looking to source sheet metal products from China.

The market for factory sheet metal types in China is growing rapidly, as more businesses look to outsource their manufacturing to leverage cost savings and access to advanced technology. SourcifyChina’s platform simplifies the sourcing process by providing a one-stop solution for finding reliable manufacturers and managing production from start to finish. With their expertise in sheet metal fabrication, they have become a go-to resource for businesses looking to streamline their supply chain and access high-quality metal products at a competitive price.

The “Sourcify China Factory sheet metal types” offer a wide range of applications in equipment manufacturing. With various sheet metal types available, manufacturers can choose the best material for their specific needs, whether it be for structural support, aesthetics, or functionality. These sheet metal types can be used in the production of equipment components such as enclosures, panels, brackets, and frames. The durability and flexibility of these materials make them ideal for use in harsh industrial environments where equipment may be subjected to extreme temperatures, corrosion, or impact.

Many industries, especially those in the manufacturing sector, rely on sheet metal fabrication for various applications. The “Sourcify China Factory sheet metal types” offers a comprehensive range of options for businesses looking to source high-quality sheet metal components. From stainless steel to aluminum, businesses can choose the material that best suits their specific needs and requirements. This allows industries to create durable and functional products such as machine parts, enclosures, and shelving units that meet industry standards and regulations.

KDM performs fabrication processes depending on your applications. If automotive parts are used as seats, door panels, or body panels, we can provide custom fabrication. Step by step processing starts from:

SourcifyChina uses various types of sheet metal in their manufacturing process. Quality control is a crucial aspect of their operations to ensure that each sheet metal piece meets the highest standards.

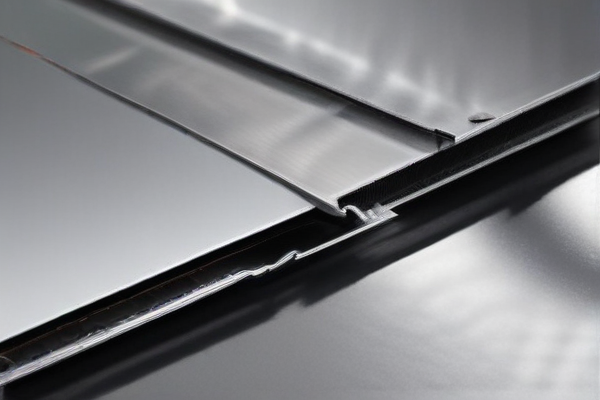

The first step in quality control is inspecting the raw materials to ensure they are of the correct type and meet the specified requirements. This helps prevent any issues that may arise during the manufacturing process.

During the fabrication process, strict quality control measures are in place to monitor the accuracy of the cuts, bends, and welds. This helps ensure that the final product will be structurally sound and meet the desired specifications.

Once the sheet metal parts are fabricated, they undergo a thorough inspection to check for any defects or imperfections. Any issues found are addressed and corrected before the parts move on to the next stage of production.

SourcifyChina offers a wide range of sheet metal types for various industrial applications. They specialize in providing high-quality materials such as stainless steel, aluminum, and carbon steel.

Their capabilities include CNC punching, laser cutting, bending, welding, and finishing services. With state-of-the-art equipment and experienced professionals, they can accurately manufacture products to meet specific requirements.

SourcifyChina’s sheet metal types are suitable for the manufacturing of components such as brackets, enclosures, panels, and frames. They can produce both simple and complex shapes with precision and efficiency.

Customers can rely on SourcifyChina for cost-effective solutions and quick turnaround times. Their expertise in sheet metal fabrication ensures high-quality products that meet industry standards.

By providing car sheet metal fabrication, we can create different car parts with excellent precision. All final auto components are engineered according to your requirements. Each part is perfect for car restoration, repair, and replacement.

We are fully capable of producing unique yet cheaper customized pieces. We are supported with advanced machines, including pipe benders, stretchers, cutting tools, and more. With more than decades of experience, KDM delivers precision and aesthetics to your projects.

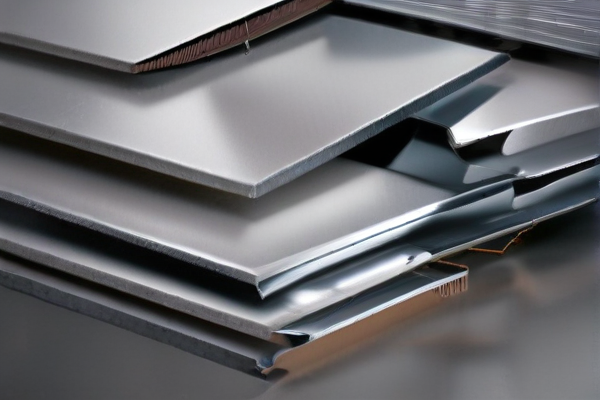

Sheet metal types offer various advantages in construction and manufacturing industries due to their versatility, durability, and cost-effectiveness.

– Sheet metal types are highly durable and resistant to corrosion, making them ideal for use in harsh environments.

– They are lightweight, making them easier to transport and install compared to other materials.

– Sheet metal can be easily formed and shaped into complex designs, allowing for customization to meet specific project requirements.

– These materials provide excellent strength and structural integrity, ensuring long-lasting performance.

– Sheet metal types are cost-effective options for various applications, helping to reduce overall project expenses.

– They also offer aesthetic appeal with a range of finishes and textures to choose from.

– Sheet metal types are recyclable, making them a sustainable choice for environmentally conscious projects.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

Sheet metal types vary in composition and thickness, influencing their characteristics and applications. Some common features include:

– Steel: Strong and durable, ideal for structural uses

– Aluminum: Lightweight and corrosion-resistant, suitable for outdoor applications

– Brass: Aesthetic and decorative, often used in architecture and art

– Copper: Excellent conductivity and malleability, commonly used in electrical components

– Stainless Steel: Resistant to rust and staining, suitable for food processing and medical equipment

– Galvanized Steel: Protected from corrosion, commonly used in outdoor structures

– Titanium: High strength-to-weight ratio, used in aerospace and medical industries

– Nickel: Excellent heat and corrosion resistance, ideal for high-temperature applications.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

SourcifyChina offers a variety of custom sheet metal types for different projects. From stainless steel to aluminum, they have options to suit various needs.

Their custom products include precision-cut parts, enclosures, brackets, and more. Each piece is made to exact specifications for a perfect fit.

SourcifyChina’s sheet metal projects range from small prototypes to large-scale production runs. They have the capability to handle projects of any size.

With state-of-the-art equipment and a team of skilled technicians, SourcifyChina ensures high-quality sheet metal products that meet industry standards.

Their dedication to excellence and attention to detail make SourcifyChina the top choice for custom sheet metal fabrication. Trust them to bring your projects to life with precision and expertise.

Some common types of sheet metal include stainless steel, aluminum, copper, and brass. Each type offers unique properties such as strength, corrosion resistance, and conductivity for various applications.

Some common types of sheet metals include aluminum, stainless steel, carbon steel, copper, and brass. Each type has unique properties and is used for different applications.

– Common types of sheet metal include stainless steel, aluminum, brass, and copper.

– Each type has its own unique properties such as strength, corrosion resistance, and ductility.

– Sheet metal is widely used in construction, manufacturing, and automotive industries for its versatility and durability.

1. Mild steel: commonly used for industrial applications due to its strength and durability.

2. Stainless steel: known for its corrosion resistance and sleek appearance, ideal for food processing and medical equipment.

3. Aluminum: lightweight and malleable, perfect for aerospace and automotive industries.

4. Copper: valued for its conductivity and aesthetic appeal, often used in roofing and electrical applications.

5. Brass: a durable alloy with a golden hue, popular in decorative elements and plumbing fixtures.

1. Aluminum – lightweight, corrosion-resistant

2. Stainless steel – durable, rust-resistant

3. Galvanized steel – coated with zinc for corrosion protection

4. Copper – conductivity, aesthetic appeal

SourcifyChina is a leading company specializing in sheet metal fabrication in China. They offer a wide range of sheet metal types including stainless steel, aluminum, brass, and copper. Their team of experienced engineers and metalworkers are dedicated to providing high-quality products that meet the specific needs of their customers. Whether it’s prototyping, small batch runs, or large volume productions, SourcifyChina has the capabilities and expertise to deliver top-notch sheet metal fabrication services. With their commitment to quality, competitive pricing, and on-time delivery, SourcifyChina is a trusted partner for businesses looking to outsource their sheet metal manufacturing needs to China.

Sheet metal plays a crucial role in the aerospace industry, where its versatility and durability make it an ideal material for a wide range of applications. One common use of sheet metal in aerospace is in the fabrication of aircraft components such as wings, fuselages, and engine parts. The lightweight nature of sheet metal makes it particularly well-suited for these applications, as it helps to reduce the overall weight of the aircraft without compromising on strength or structural integrity. In addition, sheet metal can be easily formed and shaped into complex geometries, allowing for the creation of custom components that are tailored to the specific needs of each aircraft.

Sheet metal types are widely used in the hardware industry for various applications due to their durability, versatility, and cost-effectiveness. One common application of sheet metal types in the hardware industry is in the manufacturing of metal enclosures for electronic devices such as computers, routers, and servers. These enclosures provide protection for sensitive electronic components while also allowing for proper ventilation to prevent overheating. Sheet metal types like aluminum and stainless steel are popular choices for these enclosures due to their high strength-to-weight ratio and corrosion resistance.

Sheet metal is a versatile material that is commonly used in the electronic industry for various applications. One type of sheet metal that is often used is aluminum, due to its lightweight yet strong properties. Aluminum sheet metal is often employed in the manufacture of electronic enclosures, where its strength helps to protect delicate electronic components from damage. Additionally, aluminum’s excellent corrosion resistance makes it an ideal material for electronic devices that may be exposed to harsh environments. Another common type of sheet metal used in the electronic industry is stainless steel. Stainless steel is known for its durability and resistance to corrosion, making it a popular choice for electronic components that need to withstand high temperatures or harsh chemicals. Stainless steel sheet metal is often used for casings, trays, and panels in electronic devices, providing a sleek and modern aesthetic while also ensuring the longevity of the product.

Sheet metal is a commonly used material in the automotive industry for a variety of applications. One of the most popular types of sheet metal used in this industry is steel. Steel is known for its strength and durability, making it an ideal choice for components such as body panels, chassis parts, and structural members. Additionally, steel is relatively inexpensive compared to other materials, making it a cost-effective option for mass production. Another advantage of steel sheet metal is its malleability, allowing it to be easily formed into complex shapes and designs to meet the specific requirements of different automotive components.

The medical industry relies heavily on various types of sheet metal for a wide range of applications. One common use of sheet metal in the medical field is for the manufacturing of medical equipment such as hospital beds, surgical trays, and examination tables. Sheet metal is chosen for these applications due to its durability, flexibility, and ability to be easily cleaned and sterilized. In addition, sheet metal allows for precise and intricate designs to be fabricated, making it the ideal material for complex medical equipment.

Another important application of sheet metal in the medical industry is for the production of medical cabinets and storage units. These cabinets are essential for organizing and storing medical supplies, medications, and equipment in healthcare facilities. Sheet metal cabinets are preferred for their strength, corrosion resistance, and customizable design options. Additionally, sheet metal can be easily cleaned and sanitized, ensuring a sterile storage environment for medical supplies.

1. What are the common types of sheet metal used for manufacturing quality work from SourcifyChina factory?

The common types of sheet metal used for manufacturing quality work include stainless steel, aluminum, carbon steel, and copper. These materials offer different properties such as strength, corrosion resistance, and conductivity, making them suitable for various applications.

2. How does SourcifyChina ensure the quality of sheet metal products?

SourcifyChina has a strict quality control process in place to ensure the quality of sheet metal products. This includes material testing, dimensional checks, surface quality checks, and inspection of welding and finishing techniques. The factory also works with trusted suppliers to source high-quality materials.

3. Can SourcifyChina produce custom sheet metal products according to my specifications?

When it comes to sheet metal types manufacturing from a Sourcify China factory, there are several key tips to keep in mind.

Firstly, it is important to clearly communicate your exact specifications and requirements to the factory. This includes details such as the type of sheet metal material, dimensions, thickness, and any specific features or finishes you may require.

It is also essential to work closely with the factory to ensure that they have the capabilities and expertise to meet your needs. This may involve discussing their manufacturing processes, equipment, and quality control measures to ensure that they can produce high-quality sheet metal products.

Additionally, it is important to consider factors such as production lead times, pricing, and minimum order quantities when working with a Sourcify China factory. It is advisable to negotiate these terms upfront to ensure a smooth and efficient manufacturing process.

1. Can I source different types of sheet metal from Sourcify China factory?

Yes, Sourcify China factory offers a wide range of sheet metal types including stainless steel, aluminum, copper, and more. They are equipped to manufacture custom sheet metal products according to your specifications.

2. What are the benefits of sourcing sheet metal from Sourcify China factory?

Sourcing sheet metal from Sourcify China factory can offer cost-effective solutions, high-quality products, efficient production processes, and access to a wide variety of sheet metal types and finishes.

3. How can I ensure the quality of sheet metal products sourced from Sourcify China factory?

When sourcing sheet metal types from a factory in China through SourcifyChina, there are a few tips to keep in mind to ensure a successful outcome.

First, clearly outline your specifications and requirements for the sheet metal types you need. This includes the dimensions, thickness, material composition, and surface finish. Providing detailed information upfront will help the factory better understand your needs and deliver the desired product.

Next, communicate regularly with the factory to stay updated on the production progress and address any potential issues or changes. Establishing a strong line of communication will help prevent misunderstandings and ensure that the final product meets your expectations.

It is also important to conduct thorough research on the factory’s capabilities, experience, and reputation in producing sheet metal types. Check for any certifications or quality control measures in place to verify the factory’s reliability and ability to meet industry standards.

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.