-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

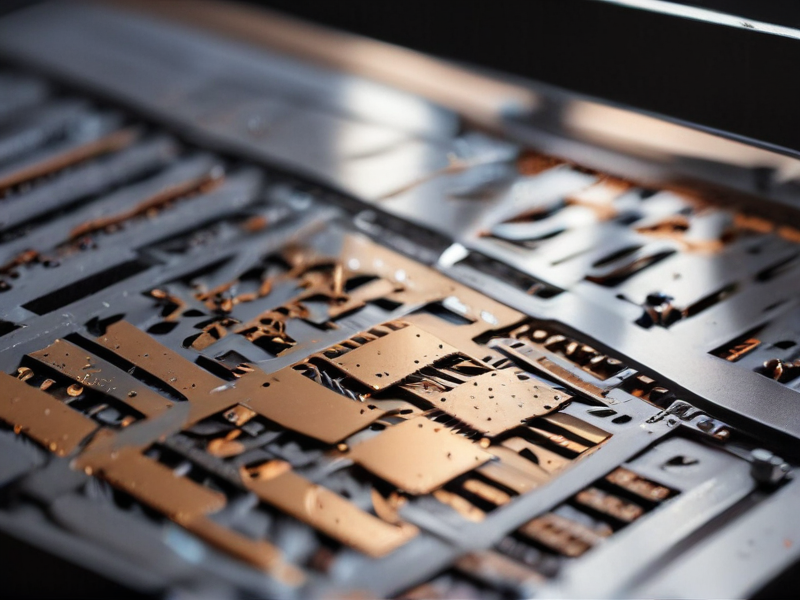

Unlock Reliable Manufacturing Solutions with Sourcify China’s Factory Laser Cutter for Metal Sheets

Sourcify China offers a cutting-edge solution for metal sheet manufacturing with its advanced factory laser cutter. When it comes to sourcing reliable manufacturing solutions in China, Sourcify is a trusted partner for businesses looking to streamline their production processes and optimize their supply chain.

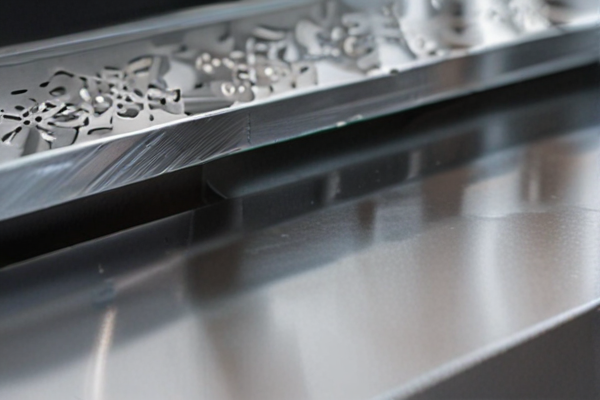

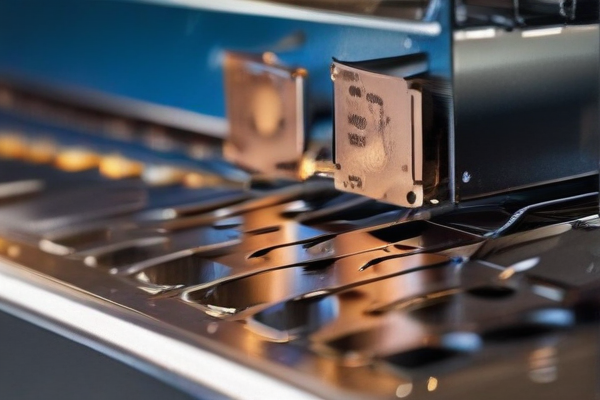

The factory laser cutter for metal sheets provided by Sourcify China is known for its precision and efficiency. With state-of-the-art technology and a team of experienced professionals, Sourcify ensures high-quality results for every project.

By partnering with Sourcify China for your metal sheet manufacturing needs, you can trust that your products will be produced with the utmost care and attention to detail. Their reliable manufacturing solutions guarantee that your projects will be completed on time and within budget.

SourcifyChina Factory offers high-quality laser cutter metal sheets at competitive prices. With advanced technology and skilled workers, we ensure precision cutting and fast delivery to meet buyer’s timelines. Our experienced team provides dedicated support to assist buyers in selecting the right products.

We prioritize quality control and adhere to strict guidelines to maintain the highest standards for our products. SourcifyChina Factory offers customization options to meet specific buyer requirements. With efficient logistics and supply chain management, we ensure smooth transactions and on-time delivery for our clients.

Buyers can trust SourcifyChina Factory for reliable and consistent supply of laser cutter metal sheets from China. With a commitment to sustainability, we strive to minimize environmental impact in our manufacturing processes. Offering competitive pricing and exceptional customer service, we are a trusted partner for buyers seeking high-quality laser cutting solutions.

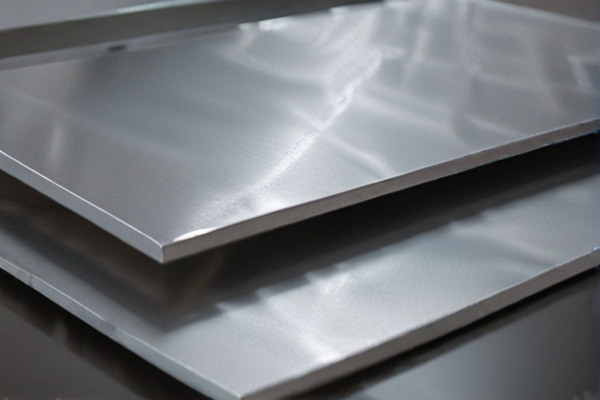

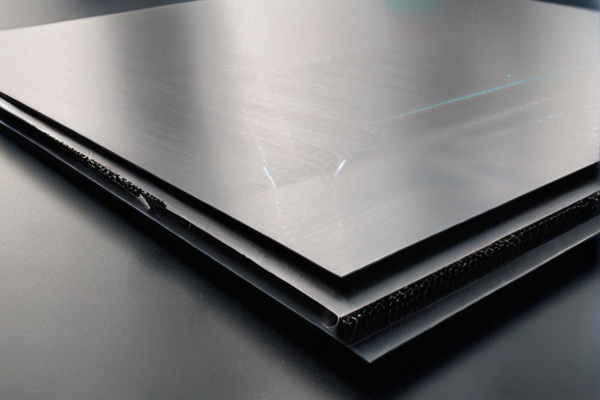

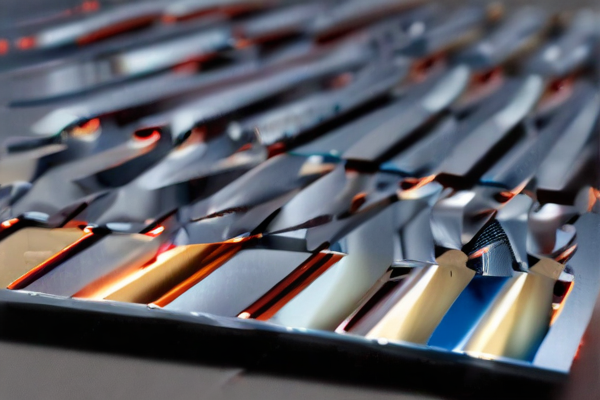

Using this technique, we turn flat metal sheets into different parts by bending, perforating, cutting, and designing. Every sheet metal can be transformed into many different forms. However, we carefully select the materials. We used high-end aluminum sheets, steel sheets, stainless steel, brass, and more. According to your exact specifications, we guarantee high-precision car sheet metal parts.

In a professional way, KDM can work with you anytime you need sheet metal components and our services. We are a well-established company with wide experience working with automotive businesses worldwide. Here, we assure you can get premium parts at fair prices. Contact us today!

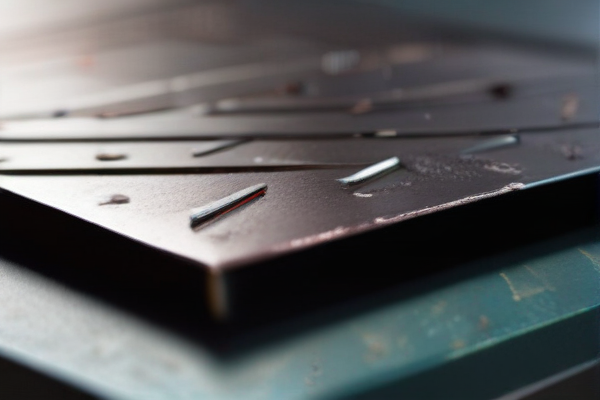

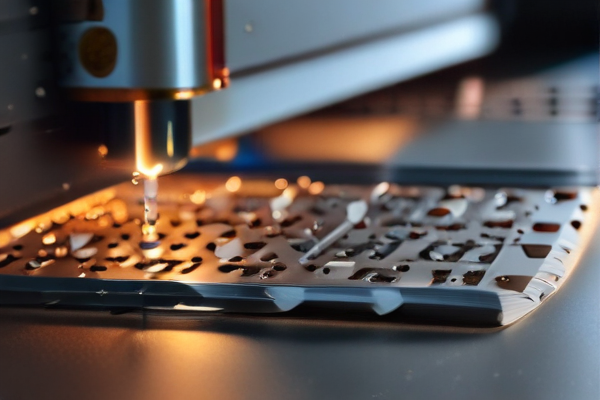

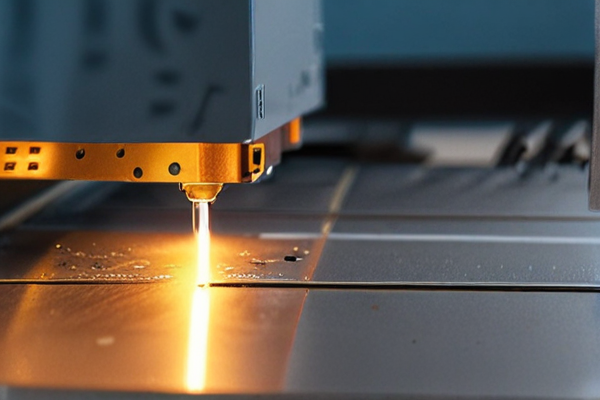

Laser cutters are machines that can cut precise shapes out of metal sheets using a high-powered laser beam.

Laser cutter metal sheets offer precision cutting capabilities for various metal materials, allowing for intricate designs and smooth edges to be achieved with ease.

A laser cutter is used to precisely cut metal sheets into desired shapes and sizes with high levels of accuracy and efficiency.

Laser cutters are used to slice through metal sheets with precision and efficiency, creating intricate designs and shapes for various industries such as manufacturing and fabrication.

Laser cutter accurately cuts metal sheets with precision and speed, creating intricate designs and producing high-quality finished products for various industries and applications.

Laser cutting is a precise method used to cut metal sheets with a high-powered laser beam, resulting in clean and accurate cuts for various industrial applications.

Each component has an excellent heat resistance and further outstanding properties. They don’t corrode, stain, or break easily.

We provide accurate fabrication services for your car sheet metal. They have high-precision designs and properties.

We offer our services for your car sheet metal at a low price. We ensure better quality yet reasonable models.

All our car sheet metal components have less maintenance. They are also easy to install and easily repairable.

When it comes to laser cutting metal sheets, there are several types and options available. Some popular choices include CO2 laser cutters, fiber laser cutters, and precision laser cutting services. Each option offers different capabilities and benefits for achieving precise and efficient metal cutting.

– CO2 laser cutters: Ideal for cutting thicker metal sheets, offering high power and versatility.

– Fiber laser cutters: Known for their high speed and precision cutting of thinner metal sheets.

– Precision laser cutting services: Utilize advanced technology for intricate and complex metal cutting projects.

– Customized laser cutting options: Tailored solutions for specific metal cutting needs and project requirements.

– Cutting capabilities: Ability to cut a wide range of metals including stainless steel, aluminum, and titanium with high accuracy and minimal heat distortion.

We used these materials for creating bulkheads, dashboards, and other car parts because of their malleability, softness, and lightweight properties. They also produce attractive polish and do not corrode, unlike other materials. We made them unbreakable as well. However, car parts made of aluminum are the most recommended ones, especially if you need durable parts for car repair or custom interior restoration.

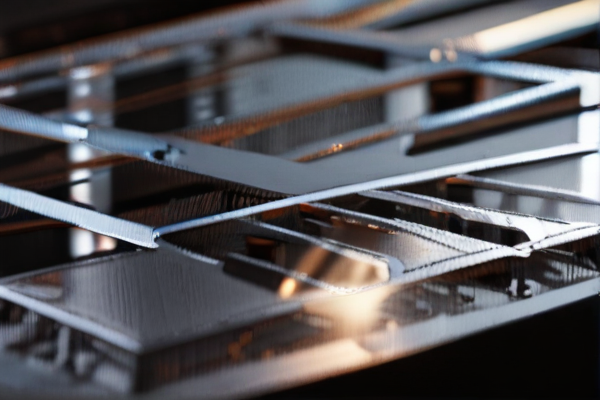

Laser cutter metal sheets can be used for various applications in manufacturing, construction, and artistic projects. With its precise cutting abilities, it can create intricate designs, custom parts, and prototypes with ease.

– Creating custom metal signs and logos

– Fabricating metal components for machinery and equipment

– Cutting intricate patterns for jewelry and artistic pieces

– Producing stencils and templates for woodworking and crafting

– Manufacturing parts for automotive and aerospace industries

– Engraving serial numbers, barcodes, and other markings on metal products

– Prototyping and testing new product designs

– Personalizing metal gifts and accessories

– Building architectural models and prototypes

– Crafting custom metal furniture and fixtures

The process is used in modifying and customizing automobile components. It is also required for precise roll-bar fabrication, vintage reconditioning, fixing or restoration process, and body reforming. So, if you are part of the automotive industry and you need a custom car parts supplier and fabrication professional, choose KDM!

The market for Sourcify China Factory laser cutter metal sheets is experiencing significant growth due to the increasing demand for precision cutting of metal sheets in various industries. The laser cutting technology offered by Sourcify China Factory is known for its high accuracy, speed, and versatility, making it a popular choice among manufacturers looking to streamline their production processes. With the ability to cut a wide range of materials, including steel, aluminum, and stainless steel, the laser cutter metal sheets from Sourcify China Factory are highly sought after for applications in automotive, aerospace, and electronics industries.

The Sourcify China Factory laser cutter for metal sheets is a game-changer in the equipment manufacturing industry. With its precision cutting capabilities, manufacturers can create intricate and complex metal components with ease. This machine is ideal for cutting a wide range of materials, including stainless steel, aluminum, and brass, making it versatile and adaptable to a variety of manufacturing needs. The high-speed cutting process ensures quick production times, allowing manufacturers to meet tight deadlines and increase efficiency in their operations.

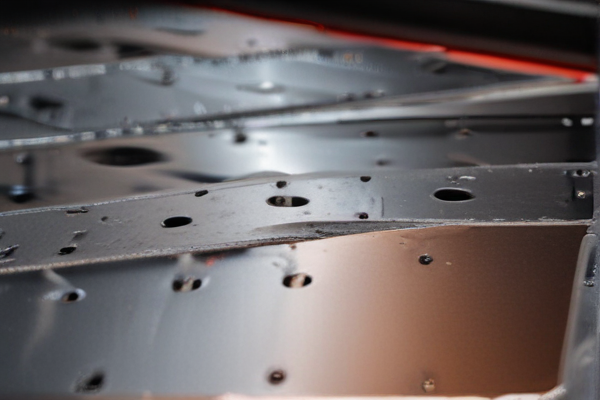

The SourcifyChina Factory laser cutter for metal sheets is a valuable tool for various industries, especially those in manufacturing and construction. With its precise cutting capabilities, this equipment can meet the high demands of industries that require intricate designs and shapes to be cut from metal sheets. For example, in the automotive industry, laser cutters are used to create precise components for vehicles, such as chassis parts and body panels. The accuracy and speed of the laser cutting process make it a cost-effective solution for producing high-quality parts in bulk.

KDM performs fabrication processes depending on your applications. If automotive parts are used as seats, door panels, or body panels, we can provide custom fabrication. Step by step processing starts from:

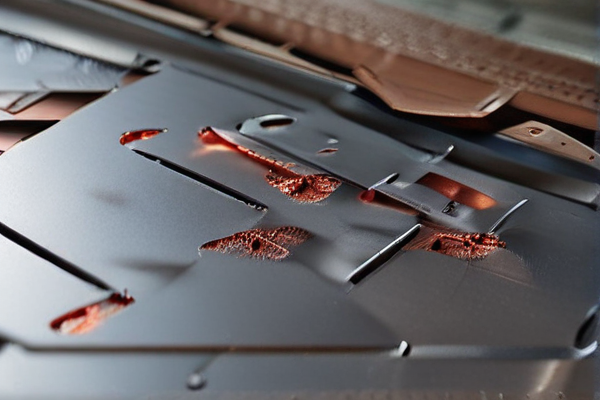

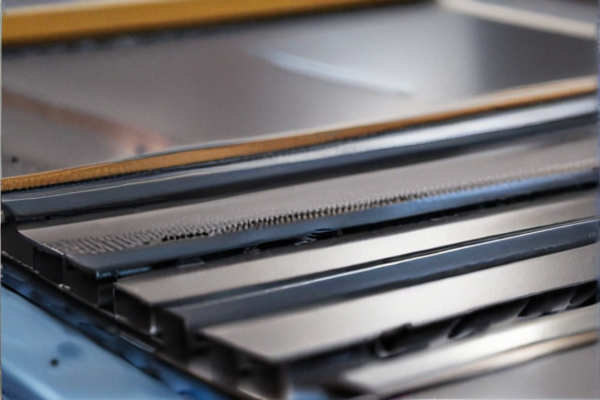

SourcifyChina’s laser cutter metal sheets undergo a rigorous quality control manufacturing process to ensure precision and durability. The process begins with careful selection of raw materials to meet quality standards.

Once the metal sheets are cut using advanced laser technology, they are thoroughly inspected for accuracy and consistency. Any imperfections or defects are immediately addressed to maintain high quality standards.

Quality control measures are implemented at every stage of the manufacturing process, including testing for strength, thickness, and overall integrity. This ensures that only top-quality metal sheets are released to customers.

In addition, SourcifyChina utilizes state-of-the-art equipment and experienced technicians to monitor and assess the quality of their laser cutter metal sheets. This commitment to quality control helps to prevent defects and ensure customer satisfaction.

SourcifyChina’s laser cutter for metal sheets offers high precision cutting capabilities for various thicknesses and types of metal. The machine is equipped with advanced laser technology to ensure clean and accurate cuts.

The laser cutter can handle a wide range of materials, including stainless steel, aluminum, copper, and more. It is ideal for intricate designs and complex shapes, providing smooth edges and minimal distortion.

With its fast cutting speeds and minimal waste, SourcifyChina’s laser cutter is a cost-effective solution for metal fabrication projects. The machine can easily cut through thick materials with high precision, making it suitable for both small-scale and large-scale production.

By providing car sheet metal fabrication, we can create different car parts with excellent precision. All final auto components are engineered according to your requirements. Each part is perfect for car restoration, repair, and replacement.

We are fully capable of producing unique yet cheaper customized pieces. We are supported with advanced machines, including pipe benders, stretchers, cutting tools, and more. With more than decades of experience, KDM delivers precision and aesthetics to your projects.

Laser cutter metal sheets offer precise and efficient cutting capabilities, allowing for intricate designs and clean edges. This technology is ideal for industries requiring high accuracy and productivity.

– Increased precision and accuracy in cutting metal sheets.

– Ability to achieve complex and intricate designs.

– Minimal material wastage leading to cost savings.

– Fast and efficient cutting process, enhancing productivity.

– Versatile in cutting various types of metal sheets.

– Minimal heat affected zone, reducing the risk of distortion.

– High repeatability of cuts, ensuring consistency in production.

– Reduces the need for manual labor and speeds up the manufacturing process.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

Laser cutters for metal sheets offer precise and clean cutting capabilities, allowing for detailed designs and intricate patterns to be easily achieved. With high accuracy and efficiency, they are ideal for a variety of applications in industries such as manufacturing and engineering.

– High precision cutting

– Smooth edges without burrs

– Versatile for various metal materials

– Minimal material wastage

– Fast cutting speed

– Ability to cut complex shapes

– Low maintenance requirements

– Computer-aided design capabilities

– Suitable for both thick and thin metal sheets

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

SourcifyChina offers custom laser-cut metal sheets for various projects. Our team specializes in creating unique products tailored to clients’ specifications.

With precision cutting technology, SourcifyChina can fabricate intricate designs on metal sheets for a wide range of applications. From decorative panels to industrial parts, we deliver high-quality results.

Our team of experienced technicians ensures that each product meets strict quality standards. We take pride in delivering durable and accurate laser-cut metal sheets for our customers.

Whether you need custom signage, architectural elements, or specialized components, SourcifyChina can turn your ideas into reality. Our personalized approach ensures that every project is executed with precision and expertise.

Laser cutters are used to precisely cut metal sheets with a high-powered laser beam, leaving clean edges and intricate designs, making them ideal for manufacturing and fabrication processes.

Laser cutting technology is used to precisely cut metal sheets with high accuracy and speed, making it a popular choice for manufacturing and industrial applications.

Laser cutters precisely cut metal sheets using a high-powered laser beam. This allows for intricate designs and shapes to be cut quickly and efficiently.

Laser cutting is a precise and efficient method for cutting metal sheets with high accuracy and clean edges using a laser beam.

Laser cutter can precisely cut metal sheets with high accuracy and efficiency, making it a popular choice for industrial applications requiring intricate designs and shapes.

SourcifyChina is a leading provider of laser cutter metal sheets in the Chinese market, offering high-quality products at competitive prices. With a focus on precision and efficiency, the company specializes in producing custom metal sheets that meet the unique needs of their clients. Their state-of-the-art laser cutting technology ensures accurate and clean cuts, resulting in products that are both aesthetically pleasing and durable. SourcifyChina’s team of skilled technicians work tirelessly to ensure that each order is completed with the utmost care and attention to detail, delivering on their promise of excellence in every aspect of their business. With a commitment to customer satisfaction and a reputation for reliability, SourcifyChina has established itself as a trusted source for laser cutter metal sheets in the industry.

The aerospace industry relies heavily on precision machining processes to manufacture components for aircraft and spacecraft. One key application of laser cutter technology in this industry is the cutting of metal sheets to create different parts and structures. Laser cutting offers several advantages over traditional cutting methods, such as plasma cutting or water jet cutting. With laser cutting, aerospace manufacturers can achieve higher precision, accuracy, and consistency in their metal sheet cutting processes. This is essential for ensuring that aircraft components fit together perfectly and meet stringent safety and performance requirements.

The hardware industry greatly benefits from the application of laser cutters for cutting metal sheets. Laser cutting technology allows for precise and intricate designs to be cut into metal sheets with minimal margin for error. This level of precision is essential in the hardware industry where products need to meet exact specifications and requirements. Whether it is cutting holes, slots, or complex shapes, laser cutters provide a level of accuracy that is unmatched by traditional cutting methods. This not only improves the quality of finished products but also reduces waste and material costs by minimizing the need for rework or adjustments.

The electronic industry extensively utilizes laser cutters for cutting metal sheets due to their precision, speed, and versatility. Laser cutting technology allows for intricate and precise designs to be cut with minimal material waste, making it ideal for creating complex electronic components with tight tolerances. Whether it’s cutting holes, slots, or intricate shapes, laser cutters can quickly and accurately cut through various thicknesses of metal sheets commonly used in the electronic industry, such as aluminum, stainless steel, and copper.

The automotive industry heavily relies on the precision and efficiency of laser cutter technology for cutting metal sheets. Laser cutters are used in the manufacturing process of creating various components for vehicles, such as car bodies, engine parts, and exhaust systems. The high accuracy and speed of laser cutting machines allow manufacturers to produce intricate and complex designs with minimal material wastage. This is essential in meeting the strict quality standards and performance requirements of modern vehicles.

The medical industry has found numerous applications for laser cutting in the production of metal sheets. One key use is in the manufacturing of surgical instruments and medical devices. Laser cutting offers a precise and accurate method for shaping metal sheets into the complex designs required for these tools. This results in products that are of high quality and meet the strict standards needed for medical equipment. Additionally, laser cutting allows for quick and efficient production processes, helping to meet the increasing demand for these specialized tools.

1. What is a laser cutting machine and how does it work?

A laser cutting machine is a tool used to cut various materials, including metal sheets, with precision using a high-powered laser beam. The laser beam is focused through a lens and directed onto the material to be cut, melting or vaporizing it along a predetermined path.

2. How does SourcifyChina ensure the quality of metal sheets cut by their laser cutter?

SourcifyChina ensures the quality of metal sheets cut by their laser cutter through rigorous quality control measures. This includes regularly calibrating and maintaining the laser cutting machine, using high-quality materials, and implementing strict quality inspection procedures throughout the manufacturing process.

3. What type of metals can be cut using a laser cutter?

Laser cutter metal sheets manufacturing is a highly efficient and precise process that can be carried out at Sourcify’s partner factories in China. Here are some tips to keep in mind when working with a laser cutter metal sheets manufacturing facility:

1. Provide detailed and accurate designs: To ensure that the metal sheets are cut precisely according to your specifications, it is essential to provide detailed and accurate design files. Make sure that all dimensions, angles, and shapes are clearly specified in the design files.

2. Specify the type of metal sheets: Inform the factory about the type of metal sheets you require for your project. Different types of metal sheets, such as stainless steel, aluminum, and copper, have different properties and cutting requirements. The factory will be able to recommend the best type of metal sheets for your project based on your requirements.

FAQ:

Q: Can I source laser cutter metal sheets from a Sourcify China factory?

A: Yes, you can definitely source laser cutter metal sheets from a Sourcify China factory. Sourcify is a leading platform for connecting businesses with manufacturers in China, and they have a wide network of reputable suppliers that specialize in metal fabrication.

Q: How do I get started with sourcing laser cutter metal sheets from a Sourcify China factory?

A: To get started, simply sign up on the Sourcify platform and submit a request for quotation for the laser cutter metal sheets you need. The Sourcify team will then connect you with suitable suppliers in their network based on your requirements.

To source laser cut metal sheets from a factory in China, follow these tips:

1. Research: Start by researching reputable factories in China that specialize in laser cutting metal sheets. Look for manufacturers with a proven track record of delivering high-quality products.

2. Verify Credentials: Ensure that the factory is registered and has the necessary certifications for metal sheet cutting. Check for any affiliations with industry associations or certifications like ISO 9001.

3. Request Samples: Before placing a large order, request samples of their laser cut metal sheets to evaluate the quality and precision of their work.

4. Negotiate Pricing: Contact multiple factories to compare quotes and negotiate pricing for your order. Be clear about your requirements and quantities to get accurate quotes.

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.