-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

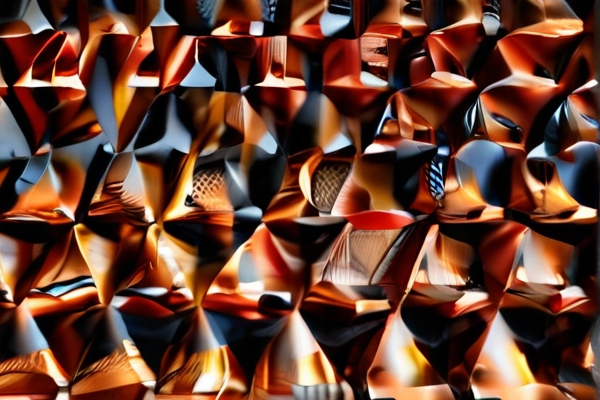

Discover the most reliable coatings for aluminum from SourcifyChina factory for durable and high-quality finishes.

SourcifyChina is a trusted factory in China for buyers looking to purchase coatings for aluminum. Their years of experience and expertise in sourcing high-quality products make them the ideal choice for businesses seeking reliable suppliers.

With a wide network of reputable manufacturers, SourcifyChina offers a variety of coating options for aluminum, ensuring that buyers can find the right product to meet their specific needs. Their commitment to quality control and product consistency sets them apart in the industry.

SourcifyChina prioritizes customer satisfaction and works closely with buyers to understand their requirements and deliver products that meet or exceed expectations. Their transparent communication and efficient process make sourcing coatings for aluminum a stress-free experience for businesses.

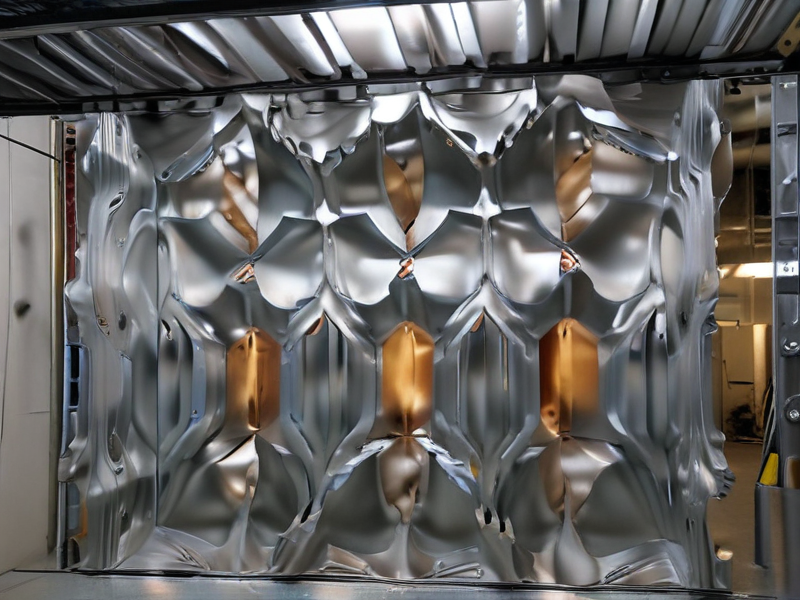

Using this technique, we turn flat metal sheets into different parts by bending, perforating, cutting, and designing. Every sheet metal can be transformed into many different forms. However, we carefully select the materials. We used high-end aluminum sheets, steel sheets, stainless steel, brass, and more. According to your exact specifications, we guarantee high-precision car sheet metal parts.

In a professional way, KDM can work with you anytime you need sheet metal components and our services. We are a well-established company with wide experience working with automotive businesses worldwide. Here, we assure you can get premium parts at fair prices. Contact us today!

1. Anodizing: Provides a durable, corrosion-resistant finish by creating a protective oxide layer on the surface of the aluminum.

2. Powder coating: Offers a smooth, durable finish that is resistant to scratches, chipping, and fading, available in a wide range of colors.

3. Chromate conversion coating: Improves adhesion for subsequent paint or adhesive applications, while also providing corrosion resistance to the aluminum surface.

4. Vinyl coating: Provides a protective layer that is resistant to chemicals, corrosion, and abrasion, ideal for outdoor applications.

5. E-coating: Offers a uniform, corrosion-resistant finish using an electrochemical process, perfect for complex-shaped aluminum parts.

6. Ceramic coating: Provides exceptional heat resistance and thermal insulation while also offering protection against corrosion and abrasion.

1. Powder coating: offers excellent durability and color options for aluminum surfaces.

2. Anodizing: provides a hard, corrosion-resistant finish that can be colored or left clear for a sleek look.

3. Epoxy coating: creates a tough, chemical-resistant barrier on aluminum that is ideal for industrial applications.

4. Thermal spray coating: enhances the wear resistance and thermal properties of aluminum surfaces for increased performance.

5. Polyurethane coating: offers a smooth, durable finish with UV protection for outdoor aluminum surfaces.

1. Anodizing: Creates a durable and corrosion-resistant oxide layer on the aluminum surface.

2. Powder coating: Offers a protective and decorative finish that is scratch-resistant and long-lasting.

3. Paint coating: Provides a versatile and customizable option for adding color and protection to aluminum surfaces.

1. Anodizing: Creates a hard, durable oxide layer on the surface of aluminum for increased corrosion resistance and improved appearance.

2. Powder coating: Applied as a dry powder and then cured under heat, this technique provides a tough finish that is resistant to chipping, scratching, and fading.

3. Polishing: Enhances the natural shine of aluminum by smoothing out any imperfections on the surface and creating a reflective finish.

4. Liquid paint: Provides a protective layer against the elements and can be customized in a variety of colors and finishes.

5. Clear coating: Adds a transparent layer to aluminum to protect it from oxidation and maintain its original appearance.

1. Anodizing: electrochemical process that creates a protective oxide layer on aluminum surface.

2. Powder Coating: electrostatically applied dry powder that forms a durable finish when heated.

3. Chromate Conversion Coating: applied as a pre-treatment for adhesion, corrosion resistance, and paint bonding.

4. Clear Coat: transparent protective layer that can be applied over aluminum for added durability and gloss.

5. Epoxy Coating: resin-based coating that provides excellent chemical and corrosion resistance on aluminum surfaces.

6. Polyurethane Coating: durable coating that offers UV protection and resistance to weathering on aluminum substrates.

7. PTFE Coating: nonstick coating that provides low friction properties and corrosion resistance on aluminum surfaces.

1. Anodizing: Forms a protective oxide layer on aluminum surface, improving corrosion resistance and enhancing durability.

2. Powder Coating: Provides a durable and decorative finish to aluminum surfaces, offering excellent resistance to chipping, scratching, and fading.

3. Paint Coating: Protects aluminum surfaces from corrosion and UV radiation, while also providing a decorative finish in various colors.

4. Clear Coat: Adds a transparent protective layer to aluminum surfaces, preserving the natural appearance while enhancing durability and resistance to wear.

5. Ceramic Coating: Offers superior protection against scratches, chemical corrosion, and extreme temperatures, making aluminum surfaces more resistant to environmental damage.

6. Epoxy Coating: Adheres to aluminum surfaces to provide a tough and resilient layer that resists chemicals, abrasion, and impact for long-lasting protection.

Each component has an excellent heat resistance and further outstanding properties. They don’t corrode, stain, or break easily.

We provide accurate fabrication services for your car sheet metal. They have high-precision designs and properties.

We offer our services for your car sheet metal at a low price. We ensure better quality yet reasonable models.

All our car sheet metal components have less maintenance. They are also easy to install and easily repairable.

There are various types of coatings available for aluminum, including anodizing, powder coating, and paint. Anodizing is a popular choice for its durability and corrosion resistance, while powder coating offers a wide range of colors and finishes. Paint can be a cost-effective option for a decorative finish.

– Anodizing: provides corrosion resistance and durability

– Powder coating: offers a variety of colors and finishes

We used these materials for creating bulkheads, dashboards, and other car parts because of their malleability, softness, and lightweight properties. They also produce attractive polish and do not corrode, unlike other materials. We made them unbreakable as well. However, car parts made of aluminum are the most recommended ones, especially if you need durable parts for car repair or custom interior restoration.

Applications for coatings for aluminum are diverse and widespread. From aerospace to automotive industries, aluminum coatings provide protection against corrosion, abrasion, and environmental factors, improving the longevity and performance of the metal.

– Aerospace: Aluminum coatings are used to protect aircraft components from harsh conditions during flight.

– Automotive: Coatings on aluminum parts prevent corrosion and enhance the appearance of vehicles.

– Construction: Aluminum coatings protect building materials from weathering and wear.

– Electronics: Coatings on aluminum components improve conductivity and provide insulation.

– Marine: Aluminum coatings protect ship hulls from seawater and marine life.

The process is used in modifying and customizing automobile components. It is also required for precise roll-bar fabrication, vintage reconditioning, fixing or restoration process, and body reforming. So, if you are part of the automotive industry and you need a custom car parts supplier and fabrication professional, choose KDM!

The market for Sourcify China Factory coatings for aluminum is a rapidly growing industry that caters to the needs of various sectors including construction, automotive, and aerospace. With the increasing demand for high-quality and durable coatings for aluminum products, manufacturers are turning to Sourcify China Factory to provide them with cost-effective solutions. The company offers a wide range of coatings including powder coating, anodizing, and electroplating, all of which are designed to enhance the durability and aesthetics of aluminum surfaces.

The use of SourcifyChina Factory coatings for aluminum in equipment manufacturing applications has proven to be highly beneficial in enhancing the durability and aesthetics of the final products. The coatings are specifically designed to provide a protective layer that prevents corrosion, scratches, and wear on aluminum components, thereby extending the lifespan of the equipment. Moreover, the coatings also improve the overall appearance of the equipment, giving it a sleek and modern finish that contributes to its marketability and consumer appeal.

The application of Sourcify’s China factory coatings for aluminum in industries such as automotive and aerospace has proven to be highly beneficial. These coatings provide a protective layer that helps to prevent corrosion and wear, extending the lifespan of aluminum components and reducing the need for frequent maintenance. In the automotive industry, these coatings are commonly used on aluminum body panels and parts to enhance their durability and resistance to environmental factors. This not only improves the overall performance and appearance of vehicles but also reduces the risk of costly repairs and replacements.

KDM performs fabrication processes depending on your applications. If automotive parts are used as seats, door panels, or body panels, we can provide custom fabrication. Step by step processing starts from:

SourcifyChina has a meticulous quality control process for manufacturing coatings for aluminum. They start by sourcing high-quality raw materials.

The raw materials are then carefully inspected for any defects or inconsistencies before being used in the production process. This ensures that only the best materials are used in the coatings.

Once the raw materials are approved, the manufacturing process begins with strict adherence to quality control standards. Each step of the process is closely monitored to maintain consistency and quality.

After the coatings are applied to the aluminum, a series of tests and inspections are conducted to ensure they meet the required specifications. This includes testing for durability, adhesion, and appearance.

SourcifyChina specializes in providing high-quality coatings for aluminum materials. Their coatings are designed to enhance the durability and aesthetics of aluminum products. With advanced technology and expertise, SourcifyChina offers a wide range of coating solutions for different industrial and commercial applications.

The coatings provided by SourcifyChina are known for their excellent adhesion and resistance to corrosion, making them ideal for outdoor applications. Whether it’s for architectural purposes or automotive components, SourcifyChina coatings can withstand harsh environmental conditions and maintain their quality over time.

SourcifyChina’s coatings for aluminum also come in a variety of colors and finishes, allowing customers to customize their products according to their preferences. From glossy to matte, textured to metallic, SourcifyChina has options to meet every design requirement.

By providing car sheet metal fabrication, we can create different car parts with excellent precision. All final auto components are engineered according to your requirements. Each part is perfect for car restoration, repair, and replacement.

We are fully capable of producing unique yet cheaper customized pieces. We are supported with advanced machines, including pipe benders, stretchers, cutting tools, and more. With more than decades of experience, KDM delivers precision and aesthetics to your projects.

Coatings for aluminum offer numerous benefits, including protection against corrosion, weathering, and wear-and-tear. These coatings can extend the lifespan of aluminum products and enhance their aesthetic appeal.

– Protection against corrosion, weathering, and wear-and-tear

– Increased lifespan of aluminum products

– Enhanced aesthetic appeal

– Resistance to chemicals and UV exposure

– Improved scratch resistance

– Easy to clean and maintain

– Increased durability and strength

– Cost-effective alternative to replacing aluminum parts

– Ability to customize coatings for specific applications

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

Coatings for aluminum offer protection against corrosion and wear, enhancing the overall durability of the material.

– Improved resistance to corrosion

– Enhanced durability

– Increased scratch and abrasion resistance

– Protection against UV rays

– Improved aesthetics with a variety of color options

– Ability to withstand harsh environmental conditions

– Coatings can be applied using various methods such as spray, dip, or powder coating

– Can help to improve the overall lifespan of the aluminum material

– Some coatings offer additional benefits such as anti-graffiti or self-cleaning properties

– Can provide a smoother surface finish for improved performance and appearance.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

SourcifyChina specializes in custom coatings for aluminum products, providing a range of solutions for various applications. With their expertise in coatings technology, they can create unique finishes to match specific project requirements.

From industrial machinery to consumer electronics, SourcifyChina has experience in delivering high-quality coatings for a wide range of aluminum products. Their custom solutions can enhance the aesthetics and durability of the products, making them stand out in the market.

SourcifyChina works closely with clients to understand their project needs and provide tailored coating solutions. Their team of experts ensures that each product receives the attention to detail it deserves, delivering exceptional results every time.

1. Anodizing: Creates a durable, corrosion-resistant layer on the aluminum surface.

2. Powder coating: Provides a tough, attractive finish using a dry powder applied electrostatically and cured with heat.

3. Paint: Offers a customizable finish with a variety of colors and protective coatings.

Some possible coatings for aluminum include anodizing, powder coating, and spray painting. These coatings can provide protection against corrosion, improve the aesthetic appearance, and enhance durability.

1. Anodized aluminum coatings provide durability and corrosion resistance.

2. Powder-coated aluminum surfaces offer a smooth, uniform finish that is resistant to chipping and scratching.

3. Clear coat lacquer protects aluminum from oxidation and enhances its natural shine.

4. Ceramic coatings create a heat-resistant barrier for aluminum components exposed to high temperatures.

Aluminum coatings offer corrosion resistance, enhanced durability, and improved aesthetic appeal for a variety of applications. They provide protection against environmental factors and extend the lifespan of aluminum surfaces.

1. Anodizing: Provides a durable, corrosion-resistant finish on aluminum by creating a protective oxide layer through an electrochemical process.

2. Powder Coating: Uses a dry powder that is electrostatically applied and then cured to create a tough and chip-resistant finish.

3. Paint: Offers endless color options and can be applied in various ways, such as spray, brush, or roller, to provide a decorative finish.

4. Cladding: Involves bonding a thin layer of another metal, such as stainless steel or copper, to aluminum for added protection and aesthetics.

SourcifyChina is a leading provider of coatings for aluminum in the Chinese market. With a focus on quality and innovation, the company offers a wide range of coatings that are designed to enhance the durability and appearance of aluminum products. SourcifyChina’s coatings are known for their superior performance, resistance to corrosion, and ability to withstand harsh environmental conditions. The company prides itself on using cutting-edge technology and materials to develop coatings that meet the highest industry standards. With a team of experienced professionals and a commitment to customer satisfaction, SourcifyChina has established itself as a trusted partner for businesses looking to enhance the quality and longevity of their aluminum products.

Coatings are widely used in the aerospace industry to protect aluminum components from corrosion, wear, and environmental damage. Aluminum is a commonly used material in aircraft manufacturing due to its lightweight properties and high strength-to-weight ratio. However, aluminum is vulnerable to corrosion when exposed to moisture and other environmental factors. Coatings provide a protective barrier for aluminum components, preventing corrosion and prolonging the lifespan of aircrafts.

In the hardware industry, coatings are commonly applied to aluminum surfaces to enhance their durability and aesthetics. Aluminum is a popular material for hardware products due to its lightweight nature and corrosion resistance, but it can still be vulnerable to wear and tear over time. By applying coatings, such as powder coatings or anodizing, the aluminum surface can be protected from scratching, chipping, and fading, ensuring that the hardware product maintains its quality and appearance for a longer period of time. Additionally, coatings can also provide aluminum surfaces with added strength and waterproofing properties, making them suitable for use in outdoor hardware applications where exposure to harsh weather conditions is a concern.

The application of coatings to aluminum surfaces in the hardware industry also offers a range of design possibilities. Coatings can be used to add color, texture, and finishes to aluminum hardware products, allowing for customization and personalization.

The electronic industry extensively utilizes coatings for aluminum components to enhance their conductivity, corrosion resistance, and reliability. Aluminum is a preferred material for electronic components due to its lightweight nature, high thermal conductivity, and excellent electrical properties. However, aluminum is susceptible to oxidation, which can compromise its performance and longevity in electronic devices. Coatings like anodizing or powder coating are commonly applied to aluminum parts to provide a protective barrier against corrosion. Anodizing forms a thin, hard oxide layer on the surface of aluminum through an electrochemical process, while powder coating involves applying a dry powder to the surface, which is then cured under heat to form a durable finish.

The automotive industry heavily relies on the application of coatings for aluminum to protect and enhance the appearance of various components. Aluminum is a popular material in the automotive industry due to its lightweight properties and ability to improve fuel efficiency. However, aluminum is susceptible to corrosion, which can greatly affect the performance and durability of vehicles. Coatings for aluminum help prevent corrosion by creating a barrier between the metal surface and environmental factors such as moisture, salt, and pollutants. These coatings also provide a protective layer that can withstand high temperatures, abrasion, and chemical exposure, ensuring the longevity of aluminum components in vehicles.

Coatings for aluminum are often used in the medical industry to enhance the durability, corrosion resistance, and biocompatibility of medical devices and equipment. One common application of coatings for aluminum in the medical field is for surgical instruments and implantable devices. These coatings can help prolong the lifespan of these instruments by protecting them from harsh sterilization processes and exposure to bodily fluids. Additionally, coatings can give these devices a smooth, non-porous surface that is easier to clean and less likely to harbor bacteria, reducing the risk of infection for patients.

1. Can SourcifyChina provide high-quality coatings for aluminum manufacturing?

Yes, SourcifyChina has a proven track record of delivering top-quality coatings for aluminum manufacturing. Our factory uses advanced technology and high-quality materials to ensure the coatings meet international standards.

2. What types of coatings do SourcifyChina offer for aluminum manufacturing?

SourcifyChina offers a wide range of coatings for aluminum, including anodizing, powder coating, and liquid paint. We can also provide custom coatings based on your specific requirements.

3. How does SourcifyChina ensure the quality of their coatings for aluminum?

When sourcing aluminum coatings for manufacturing from SourcifyChina, there are a few key tips to keep in mind:

1. Understand the requirements: Before reaching out to the factory, have a clear understanding of the specific requirements for the aluminum coatings. This includes factors such as the desired finish, thickness, durability, and any industry-specific standards that need to be met.

2. Request samples: Before placing a large order, request samples of the different coatings available from the factory. This will allow you to test the quality and performance of the coatings to ensure they meet your expectations.

3. Consider environmental standards: If environmental sustainability is important to your manufacturing process, inquire about the factory’s environmental standards and the types of coatings they offer that are environmentally friendly.

What types of coatings are available for aluminum products from SourcifyChina factory?

SourcifyChina factory offers a variety of coatings for aluminum products, including but not limited to anodizing, powder coating, painting, and plating. Anodizing is a popular choice for aluminum as it increases its corrosion resistance and durability. Powder coating provides a durable and attractive finish, while painting allows for a wide range of color options. Plating can also be used to enhance the appearance and protect the aluminum.

How do I ensure the coatings on my aluminum products from SourcifyChina factory are high quality?

When sourcing coatings for aluminum from a SourcifyChina factory, there are several tips to keep in mind:

1. Research and vet potential suppliers: Before selecting a factory, conduct thorough research on their reputation, quality of products, and experience with coatings for aluminum. Look for online reviews, request samples, and ask for references from past clients.

2. Specify your requirements: Clearly communicate your requirements for the coatings, including desired specifications, colors, finishes, and quantities. Provide detailed instructions to ensure the factory can meet your needs accurately.

3. Consider the factory’s expertise: Look for a factory that specializes in coatings for aluminum and has a proven track record of producing high-quality products. Ensure they have the necessary equipment, technology, and expertise to deliver the coatings you require.

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.