-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

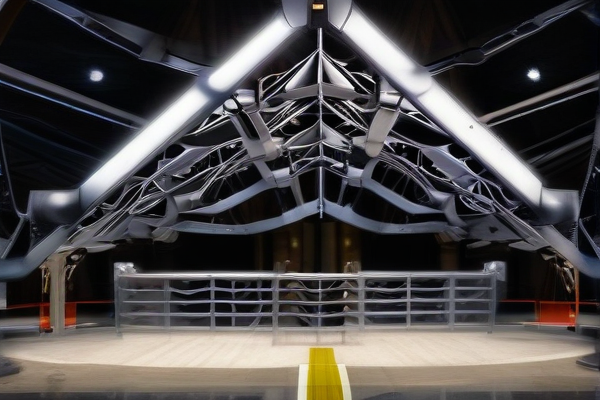

Unlocking Reliable Steel Structure Fabrication with Sourcify China Factory

Sourcify is revolutionizing the way steel structures are fabricated with their reliable manufacturing processes in China. With Sourcify’s experienced team and trusted network of factories, clients can confidently source high-quality steel structures for their projects.

Sourcify offers a streamlined approach to sourcing steel structures, ensuring that clients receive top-notch products at competitive prices. By partnering with Sourcify, clients can take advantage of the cost savings associated with manufacturing in China without sacrificing quality or reliability.

The experienced team at Sourcify carefully selects and vetoes factories to ensure that they meet the highest standards of quality and reliability. From design to production, Sourcify oversees every step of the process to guarantee that clients receive reliable steel structures that meet their exact specifications.

SourcifyChina is a trusted factory in China for purchasing fabrication steel structures. With years of experience, they offer high-quality products at competitive prices. Their team of experts ensures a smooth buying process from start to finish.

SourcifyChina stands out for their strict quality control measures, ensuring that every steel structure meets industry standards. They also have a wide range of customization options to meet the specific needs of each buyer. This attention to detail sets them apart from other factories in China.

Buyers can rely on SourcifyChina’s efficient production team to deliver orders on time. The factory’s streamlined processes and strong relationships with shipping partners result in timely delivery of steel structures without compromising on quality. This reliability is a key factor in choosing SourcifyChina for purchasing steel fabrication.

Using this technique, we turn flat metal sheets into different parts by bending, perforating, cutting, and designing. Every sheet metal can be transformed into many different forms. However, we carefully select the materials. We used high-end aluminum sheets, steel sheets, stainless steel, brass, and more. According to your exact specifications, we guarantee high-precision car sheet metal parts.

In a professional way, KDM can work with you anytime you need sheet metal components and our services. We are a well-established company with wide experience working with automotive businesses worldwide. Here, we assure you can get premium parts at fair prices. Contact us today!

We specialize in custom fabrication of steel structures for industrial, commercial, and residential projects. Our experienced team ensures high quality and timely delivery.

Fabrication of steel structures involves cutting, bending, and assembling steel materials to create sturdy frames for buildings, bridges, and other infrastructure projects.

Fabrication of steel structures involves cutting, bending, and assembling steel components to create buildings, bridges, or other structures that are durable and strong.

We specialize in the fabrication of steel structures, providing quality products tailored to meet our customers’ needs for construction projects of all sizes.

Fabrication of steel structures involves the manufacturing and assembly of steel components to create a strong and durable framework used in construction projects.

Fabrication of steel structures involves cutting, shaping, and assembling steel components to create durable and stable frameworks for various construction projects.

Each component has an excellent heat resistance and further outstanding properties. They don’t corrode, stain, or break easily.

We provide accurate fabrication services for your car sheet metal. They have high-precision designs and properties.

We offer our services for your car sheet metal at a low price. We ensure better quality yet reasonable models.

All our car sheet metal components have less maintenance. They are also easy to install and easily repairable.

There are various types of fabrication steel structures available for construction projects. These options include:

– Structural steel frames

– Steel trusses

– Steel beams and columns

– Steel plates and angles

– Welded steel members

– Prefabricated steel buildings

– Steel reinforcements for concrete structures

– Steel staircases and handrails

– Custom steel fabrications for specific project requirements

– Galvanized or painted steel for corrosion protection.

We used these materials for creating bulkheads, dashboards, and other car parts because of their malleability, softness, and lightweight properties. They also produce attractive polish and do not corrode, unlike other materials. We made them unbreakable as well. However, car parts made of aluminum are the most recommended ones, especially if you need durable parts for car repair or custom interior restoration.

Fabrication steel structures are commonly used in various applications such as construction, industrial facilities, bridges, and transportation infrastructure. These structures provide durable and strong support for buildings, equipment, and bridges.

– Construction: used in building skyscrapers, commercial buildings, and residential homes

– Industrial facilities: provide support for heavy machinery and equipment

– Bridges: used to construct bridges for roadways and pedestrian paths

The process is used in modifying and customizing automobile components. It is also required for precise roll-bar fabrication, vintage reconditioning, fixing or restoration process, and body reforming. So, if you are part of the automotive industry and you need a custom car parts supplier and fabrication professional, choose KDM!

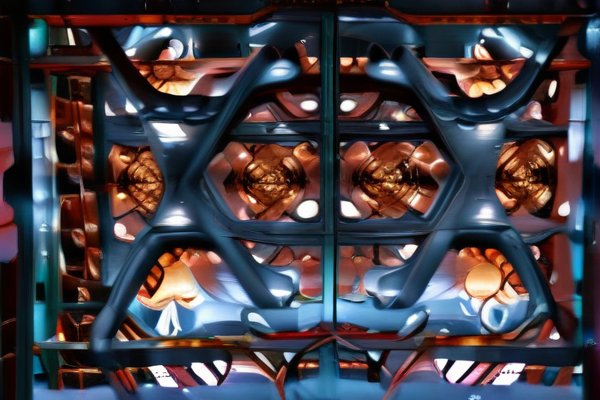

The Sourcify China Factory is a leading provider of steel structure fabrication services in the Chinese market. With years of experience and a skilled workforce, they have established themselves as a reliable and trusted partner for companies looking to outsource their steel structure fabrication needs. The China Factory is equipped with state-of-the-art machinery and technology, allowing them to produce high-quality steel structures that meet industry standards. Whether it is for construction projects, industrial buildings, or infrastructure development, the Sourcify China Factory has the capabilities to deliver custom solutions that meet their clients’ specific requirements.

Sourcify’s China factory offers fabrication services for steel structures that find application in the manufacturing of equipment. Steel structures are essential components in the manufacturing industry as they provide the necessary support and framework for various types of equipment. Whether it is for heavy machinery or specialized equipment used in the production process, steel structures fabricated at Sourcify’s China factory ensure durability and reliability. Fabricated steel structures play a crucial role in maintaining the structural integrity of equipment, often serving as the framework that holds critical components in place. With Sourcify’s expertise in steel fabrication, manufacturers can rely on high-quality steel structures that meet industry standards and specifications for their equipment manufacturing needs.

Sourcify China Factory’s fabrication of steel structures has been widely adopted across various industries for its reliability, efficiency, and cost-effectiveness. The automotive industry, for example, has leveraged Sourcify’s steel structures for the construction of manufacturing plants, assembly lines, and warehouses. The robust nature of the steel structures provides a secure environment for storing heavy equipment and machinery. Additionally, the precise fabrication process ensures that the structures are tailor-made to meet the specific requirements of the automotive industry, such as load-bearing capacity and durability. This enables automotive companies to streamline their operations and enhance productivity while minimizing maintenance costs in the long run.

KDM performs fabrication processes depending on your applications. If automotive parts are used as seats, door panels, or body panels, we can provide custom fabrication. Step by step processing starts from:

SourcifyChina implements a strict quality control process for fabricating steel structures. This process involves inspecting materials and parts before assembly to ensure they meet standards.

Each steel component is carefully checked for defects or imperfections to prevent any issues during the manufacturing process. Any subpar materials are promptly removed and replaced with high-quality alternatives.

During the assembly phase, highly skilled technicians meticulously weld, cut, and shape the steel to precise specifications. This helps guarantee that the final product meets the required standards for strength and durability.

Once the steel structure is fully assembled, a series of rigorous tests are conducted to assess its performance and safety. This includes load testing, stress testing, and quality assurance checks to ensure the structure is safe and reliable.

SourcifyChina specializes in fabrication of steel structures. They have the capability to fabricate a wide range of steel structures for various industries.

Their team of experienced professionals can design and create customized steel structures according to the specific needs of their clients.

SourcifyChina is equipped with state-of-the-art technology and machinery to ensure precision and accuracy in their fabrication process.

They have a strong quality control system in place to ensure that all fabricated steel structures meet industry standards and client requirements.

With their expertise and dedication to quality, SourcifyChina is the trusted partner for fabricating steel structures for projects of all sizes. Whether it’s a small structure or a large complex, they have the capability to deliver on time and within budget, while maintaining the highest level of quality and craftsmanship.

By providing car sheet metal fabrication, we can create different car parts with excellent precision. All final auto components are engineered according to your requirements. Each part is perfect for car restoration, repair, and replacement.

We are fully capable of producing unique yet cheaper customized pieces. We are supported with advanced machines, including pipe benders, stretchers, cutting tools, and more. With more than decades of experience, KDM delivers precision and aesthetics to your projects.

Fabrication steel structures offer numerous benefits, including durability, cost-effectiveness, and customization options.

– Durability: Steel is a strong and durable material that can withstand harsh weather conditions and environmental factors.

– Cost-effectiveness: Steel structures are often more cost-effective than other building materials, as they require less maintenance and have a longer lifespan.

– Customization options: Steel structures can be easily modified or expanded to suit specific needs or preferences.

– Sustainability: Steel is a recyclable material, making it an environmentally friendly option for construction projects.

– Speed of construction: Steel structures can be fabricated off-site and assembled quickly, reducing construction time.

– Fire resistance: Steel is non-combustible, offering increased fire safety compared to other building materials.

– Versatility: Steel can be used for a variety of structures, from warehouses to office buildings to bridges.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

Fabrication steel structures are known for their durability, strength, and versatility in construction projects. These structures can be easily customized to meet specific project requirements.

– Customizable designs to fit any project specifications

– Quick assembly and installation process

– Excellent strength-to-weight ratio, making them ideal for tall buildings

– Resistant to fire, rust, and corrosion for long-lasting performance

– Environmentally friendly, as steel is easily recyclable

– Cost-effective compared to other construction materials

– Can withstand harsh weather conditions and natural disasters

– Allows for future modifications and expansion with minimal disruptions.

Toughness: We offer automotive parts with extreme toughness. It is made from high-grade and durable sheet metals.

SourcifyChina specializes in custom fabrication of steel structures for various projects. With high-quality materials and skilled craftsmanship, they can create tailor-made products to meet client specifications.

Their fabrication capabilities include manufacturing steel beams, columns, trusses, and frames, ensuring durability and strength in every project. SourcifyChina also offers customization options for design, dimensions, and finishes to suit individual needs.

From commercial warehouses to residential buildings, SourcifyChina has experience in delivering custom steel structures for a wide range of applications. Their team of experts ensures precise fabrication and timely delivery, making them a reliable choice for projects of any size.

Fabrication of steel structures involves the process of cutting, bending, and assembling steel components to create a strong and durable framework for buildings, bridges, and other infrastructure projects.

Fabrication of steel structures involves cutting, shaping, and assembling steel components to create durable and reliable frameworks for buildings, bridges, and other infrastructure projects.

We specialize in the fabrication of high-quality steel structures for various industries. Our experienced team ensures precision and efficiency in every project we undertake.

We specialize in fabricating steel structures for various industries, providing high-quality and customized solutions for our clients’ specific needs. Contact us for expert fabrication services.

Fabrication of steel structures involves cutting, bending, and assembling raw steel materials to construct buildings, bridges, and other architectural elements.

SourcifyChina is a leading company specializing in the fabrication of steel structures for a wide range of industries. With years of experience and a team of skilled engineers and fabricators, the company is known for delivering high-quality products that meet strict industry standards. SourcifyChina prides itself on its dedication to customer satisfaction and its ability to customize designs to meet specific project requirements. The company has a reputation for delivering projects on time and within budget, making it a trusted partner for clients looking for reliable steel fabrication solutions. Whether the project is large or small, SourcifyChina’s commitment to quality and professionalism sets it apart in the industry.

The aerospace industry extensively relies on fabrication steel structures for various applications. Steel structures are commonly used in the construction of hangars, assembly facilities, and maintenance buildings for aircraft. These structures are known for their high strength-to-weight ratio, allowing them to withstand the heavy loads and harsh conditions within the aerospace environment. Steel structures can also be prefabricated offsite, minimizing construction time and costs while ensuring precision in the assembly process.

The hardware industry often relies on fabrication steel structures for a variety of applications. These structures are used in the construction of warehouses, factories, and other industrial facilities, providing durable and sturdy foundations for heavy machinery and equipment. Fabrication steel structures are also commonly used in the production of agricultural buildings and storage facilities, offering a cost-effective and long-lasting solution for farmers and agricultural businesses.

The electronic industry heavily relies on fabrication steel structures for various applications. These structures provide essential support for electronic equipment and machinery in manufacturing facilities and data centers. Steel structures are used to house servers, control panels, and other devices that are crucial for the operation of electronic systems. The strength and durability of steel make it an ideal material for supporting heavy equipment and ensuring the safety of workers in these environments. Additionally, steel structures can be customized to meet the specific needs of different electronic industry applications, such as providing efficient cable management and ensuring proper ventilation for sensitive equipment.

The automotive industry relies heavily on the use of fabricated steel structures for a variety of applications. These structures are utilized in the manufacturing process of vehicles, as they provide the necessary support and framework for assembling components. Fabricated steel structures also play a crucial role in the construction of automotive production facilities, providing a durable and versatile option for building design. In addition, steel structures are used to create storage facilities and warehouses to store automotive parts and supplies, ensuring efficient operations and accessibility.

The medical industry has a significant need for the application of fabrication steel structures in various aspects of its operations. One key application is the construction of medical facilities such as hospitals, clinics, and research laboratories. These structures require sturdy and durable materials to ensure the safety and integrity of the building, as well as the equipment housed within. Fabrication steel structures provide the strength and stability needed to support medical equipment, machinery, and infrastructure essential for providing high-quality healthcare services. By using steel structures, medical facilities can be built with precision and efficiency, allowing for the customization of layouts to accommodate specific medical needs and requirements.

1. How can I ensure the quality of fabrication steel structures from SourcifyChina factory?

At SourcifyChina, our skilled engineers and quality control team monitor every step of the manufacturing process to ensure top-notch quality. We also conduct thorough inspections and tests before shipment to ensure that the fabrication steel structures meet your specifications and standards.

2. Can I customize the steel structures according to my specific requirements?

Yes, we offer customized fabrication services to meet your unique requirements. Our team of expert engineers will work closely with you to understand and implement your design specifications, ensuring that the final product meets your expectations.

3. What types of fabrication steel structures can SourcifyChina produce?

SourcifyChina is a leading factory in China specializing in the fabrication of steel structures. When working with SourcifyChina, there are some tips to ensure a successful manufacturing process.

1. Clear Communication: Communication is key when working with a factory in China. Make sure to clearly communicate your requirements, specifications, and expectations to SourcifyChina to avoid any misunderstandings.

2. Quality Control: SourcifyChina is known for its high-quality manufacturing processes. However, it is important to implement quality control measures to ensure that the steel structures meet your standards. Consider conducting regular inspections or using third-party quality control services.

3. Timely Updates: Stay in constant communication with SourcifyChina to receive timely updates on the progress of your order. This will help you track the manufacturing process and address any issues or delays promptly.

1. What is the process of sourcing fabrication steel structures from a SourcifyChina factory?

To source fabrication steel structures from a SourcifyChina factory, you would first need to provide detailed specifications and requirements for your project. SourcifyChina will then match you with a suitable factory that specializes in steel structure fabrication. The factory will provide samples for your approval, after which production will commence. Quality control checks will be conducted throughout the manufacturing process, and once completed, your products will be shipped to your desired location.

2. How long does it take to fabricate steel structures at a SourcifyChina factory?

1. Begin by conducting thorough research on reputable steel structure fabrication factories in China. Utilize online platforms such as SourcifyChina to search for manufacturers with positive reviews and a proven track record of producing high-quality steel structures.

2. Narrow down your search by filtering factories based on factors such as location, production capacity, and specialization in steel fabrication. Look for manufacturers that offer competitive pricing without compromising on the quality of their products.

3. Reach out to the selected factories directly through SourcifyChina’s platform to request quotes, samples, and detailed information about their manufacturing processes. Ask for certifications and quality control measures to ensure that the factory meets industry standards.

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.