-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

“Unleash the power of SourcifyChina for reliable factory laser etching services on metal. Experience precision and quality like never before.”

At SourcifyChina, we understand the importance of high-quality laser etching services on metal. Whether you’re looking to add branding, product information, or intricate designs to your metal products, our experienced team can deliver precision and perfection every time.

We work closely with a network of trusted factories in China that specialize in laser etching on metal. These factories are equipped with state-of-the-art laser technology and employ skilled technicians who ensure that every etching is accurate and precise. We quality check every finished product to ensure that it meets our rigorous standards before it reaches you.

By choosing SourcifyChina for your factory laser etching needs, you can rest assured that you’re getting reliable and top-notch service.

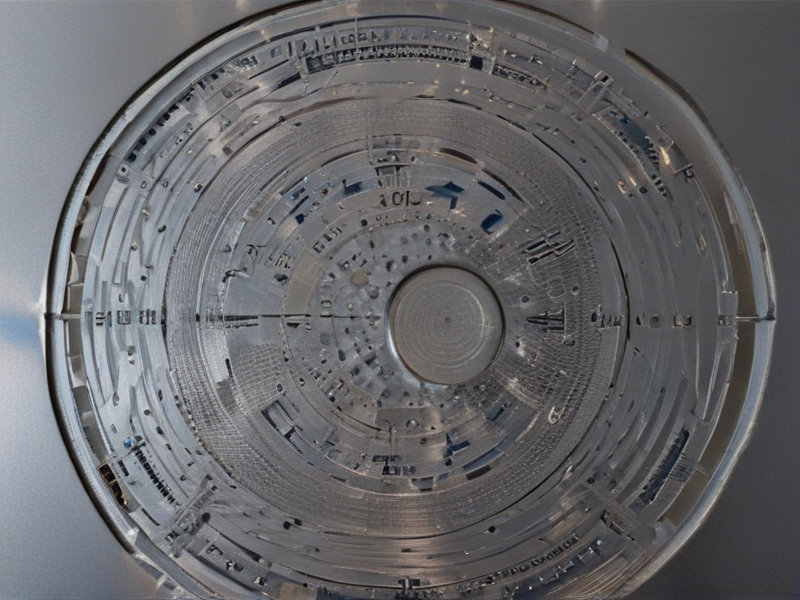

SourcifyChina laser etching on metal provides precise and permanent markings that are resistant to wear and tear. This ensures longevity and durability of the product, making it ideal for high-use items. Additionally, the detailed etching allows for intricate designs to be easily translated onto the metal surface.

The laser etching process is highly customizable, offering the flexibility to create unique and personalized markings on metal items. This allows for branding, serial numbers, logos, or any other specific information to be accurately and consistently produced. It provides a professional and polished finish that adds value to the product.

SourcifyChina offers laser etching on metal, providing precise and detailed markings on various types of materials. The technology allows for customization with logos, serial numbers, and text.

The laser etching process ensures high durability and resistance to wear and corrosion, making it an ideal solution for permanent markings on metal surfaces. The technique provides a clean and professional finish that enhances the overall appearance of the product.

With SourcifyChina’s laser etching service, intricate designs can be achieved with great precision and accuracy, resulting in crisp and clear markings. This allows for complex patterns and detailed graphics to be etched onto metal surfaces with ease.

The laser etching process on metal offers a fast and efficient solution for adding permanent markings without causing any damage to the material. It is a cost-effective method that provides consistent results without compromising on quality.

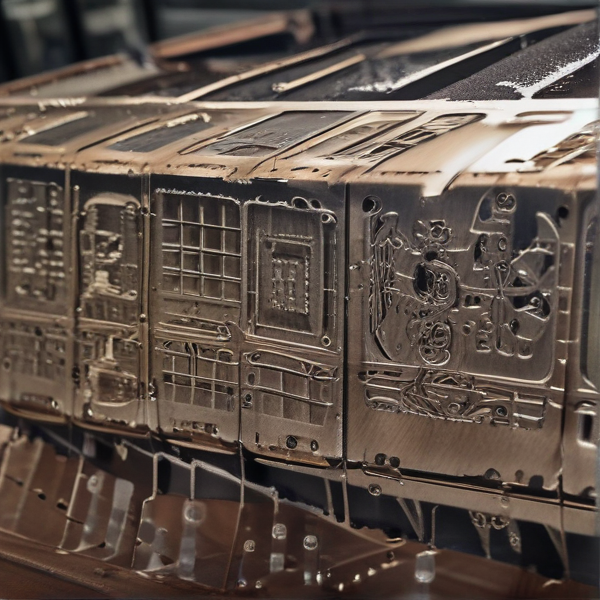

SourcifyChina Factory specializes in laser etching on metal surfaces. This process is commonly used for creating permanent markings on various materials such as stainless steel, aluminum, and brass.

Laser etching is a versatile technique that can be employed for a wide range of applications, including part identification, branding, serial numbering, and decorative engraving. It provides a high-quality, precise finish that is resistant to wear and tear.

The process of laser etching involves using a focused laser beam to vaporize the surface of the material, creating a permanent mark. This results in a clean, precise, and highly-detailed engraving that can be customized to meet the specific requirements of the project.

SourcifyChina factory offers high-quality laser etching services for metal products, ensuring precise and durable results. Their experienced team and advanced technology make them a reliable choice for buyers looking for top-notch customization.

With competitive pricing and efficient production processes, SourcifyChina can provide cost-effective solutions for bulk orders of laser etched metal products. Their streamlined workflow and attention to detail guarantee timely delivery without compromising quality.

Moreover, SourcifyChina’s strict quality control measures ensure that every laser etched metal product meets the highest standards. From material selection to final inspection, their commitment to excellence is evident in the flawless finish of each item.

Enhance Your Branding and Product Quality with Sourcify China Factory’s Precision Laser Etching on Metal

Looking to elevate your product’s branding and quality? Look no further than Sourcify China Factory’s top-of-the-line laser etching on metal services. With our advanced technology and expert team, we can help bring your designs to life with incredible precision and detail.

Laser etching on metal offers a multitude of applications for businesses in various industries. Whether you’re in the electronics, automotive, or jewelry industry, this innovative technique can add a personalized touch to your products. From serial numbers and logos to intricate patterns and graphics, the possibilities are endless with our laser etching services.

SourcifyChina’s factory laser etching on metal technology is a game-changer for the automotive industry. By using advanced laser technology, manufacturers can create intricate and precise designs on metal components, providing a more professional and sleek finish. This technology allows for branding, serial numbers, barcodes, and other essential information to be etched onto a wide range of automotive parts. This not only helps in providing a unique identity to each component but also ensures traceability and authenticity, which is crucial in the automotive industry to prevent counterfeiting and ensure quality control.

One common application of laser etching on metal in equipment manufacturing is for the branding and identification of products. By using laser etching, manufacturers can easily engrave logos, serial numbers, and other important information on metal components. This not only adds a professional and high-quality finish to the product but also helps in ensuring traceability and authenticity. Additionally, laser etching on metal provides a permanent and durable marking that is resistant to wear and corrosion, making it ideal for use in harsh industrial environments.

Sourcify China Factory ensures quality laser etching on metal through rigorous quality control measures. They carefully inspect each metal piece before the laser etching process to ensure that there are no defects or imperfections that could affect the final result. This thorough inspection helps to guarantee that the etching is precise and consistent on each piece.

During the laser etching process, Sourcify China Factory uses advanced technology and equipment to ensure that the etching is done with the utmost precision and accuracy. They have skilled technicians who are trained to operate the equipment and monitor the etching process to make sure that the quality standards are met. This attention to detail helps to produce high-quality metal pieces with clear and sharp etching.

Since 2013, this client from the United States has purchased numerous filling machines for both CBD and eliquid oil.

What type of laser machine does SourcifyChina use for laser etching on metal?

SourcifyChina uses state-of-the-art fiber laser machines specifically designed for high-quality metal etching. These machines offer precise and detailed etching capabilities while ensuring a consistent and reliable outcome.

How does SourcifyChina ensure the quality of laser etching on metal?

SourcifyChina employs a team of experienced engineers and technicians who carefully oversee the entire etching process. They conduct thorough quality checks at every stage to ensure that the final product meets customer requirements.

Can SourcifyChina handle complex designs for laser etching on metal?

Laser etching on metal is a precise and efficient method of adding designs, logos, or information to metal surfaces. Here are some key tips to keep in mind when working with a SourcifyChina factory for laser etching on metal manufacturing:

1. Clear Communication: Clearly communicate your design requirements, including the size, placement, and depth of the etching. Providing detailed specifications will help ensure that the factory can produce the desired results.

2. Material Selection: Different metals may react differently to laser etching. Work with the factory to select the most suitable metal for your project to achieve the best results.

3. Quality Control: Insist on high-quality control measures to guarantee the precision and accuracy of the etching process. Regularly inspect samples to ensure that the finished products meet your standards.

1. What is laser etching on metal?

Laser etching on metal is a process that uses a laser to create permanent markings or designs on metal surfaces. The laser beam removes layers of the metal to reveal the desired image or text.

2. What types of metals can be laser-etched?

Laser etching is commonly used on metals such as stainless steel, aluminum, titanium, brass, and copper. The type of metal used will affect the final look of the etched design.

3. What are the advantages of laser etching on metal?

Laser etching on metal provides precise and permanent markings without affecting the integrity of the metal. It is a fast and cost-effective method for creating custom designs on metal surfaces.

When sourcing laser etching on metal from a factory in China, it is important to consider a few key factors. Firstly, make sure to conduct thorough research on potential suppliers to ensure they have the necessary expertise and equipment for high-quality laser etching on metal.

Next, communicate your specific requirements clearly with the factory to avoid any misunderstandings or errors in the final product. Provide detailed designs, dimensions, and any other specifications to ensure the etching is done accurately.

It is also important to discuss the quantity of the order with the factory to ensure they can meet your production needs. Consider factors such as lead time, production capacity, and shipping options to determine if the factory is a good fit for your project.

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.