-

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

- Newsletter

- Whatsapp 8615951276160

- Industry

- Material

- Capability

- Products

- Blog

- Sitemap

Being one of the modern manufacturing technique CNC machines use computer programming codes often called G codes, Computerized Numeric Control to add automation, efficiency, effectiveness, precision, accuracy and environmental friendly practices like reduction in waste as compared to conventional lathe and milling machines that require human attention throughout the manufacturing process hence its more prone to failure of the job because of human negligence and errors.

In Production and manufacturing sector Subtractive Manufacturing way of fabricating industrial or commercial parts is a common practice and widely used for mass production. CNC Milling, CNC Turning, CNC EDM, CNC Plasma Cutting, CNC laser Engraving, NC Water Jet Cutter, CNC Grinding, etc., Machines which are very common over the variety of industrial and commercial sector.

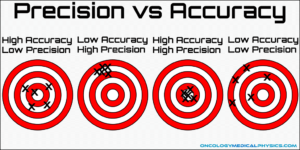

Precision and Accuracy is very important in Designing and Manufacturing as it helps the parts produced by any operation either by conventional machining or by CNC machining to function as end user intends. To cater for this important notion is of critical importance and not only precision but accuracy also is very important.

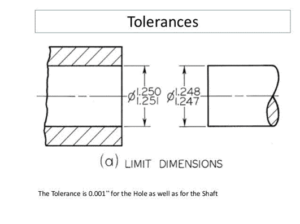

Tolerance is of vital importance for any manufacturer and end user as it’s the allowed deviation or variation in a physical dimension of a part or product. It is the range in which dimensions can vary and within the acceptable limits and can be used as per drawings of design. If assemblies of multiple parts accurately fit to each other this means all the parts are precisely designed and manufactured and are respecting the allowed deviation and tolerances.

Hence, mostly the tolerances in microns are specified on engineering drawings and are essential for guiding the manufacturing process as well as the Precision CNC Machining. By using Computerized Numeric Control in Milling, Turning, etc. Machines high accurate and precise complex and functionally critical parts with tight tolerances are made to be used in industries like aerospace, automotive, medical devices, electronics, etc. where precision, quality and efficiency are of dire importance. Different type of materials depending upon the use of product can be utilized to manufacture it using Precision CNC Machining like aluminum, steel, titanium, etc.

Considering the two important factors Precision CNC Machining needs very sound, effective, well maintained functionally accurate and well calibrated CNC equipment as high spindle speed of milling or turning machines working on part mounted to the work table that moves in xyz or more axis, Wuxi Lead Precision Machinery produces parts that can withstand highly demanding work so that large number parts with tight tolerance can be produce and users can get what they paid for.

As CNC provides repeatability so Precision CNC Machining offers production of large scale parts with no compromise on breaching the allowed tolerance and precision therefore customer can be rest assured that if one part from the lot is precise and as per desired tolerance then all the followed parts will be identical without human error and will be the same with no deviation.

If somehow deviation occurs the Quality control team at Wuxi Lead Precision Machinery take care of it as we our offer services without any delay in completion time as Diverse and State of the art Precision CNC machines are capable of Low volume, Small batch to large scale production without defected parts as our Quality Control team passes the part only with 100% compliance.

Coordinate Measuring Machine Thread and Ring Gages, Vertical Measuring System Micro-Hardness Tester and Transfer Gage are some state of the art equipment that we possess in our arsenal that help us to maintain Zero Defect part Policy by complete check and balance of the work.

Efficiency of Precision CNC machines is very high with continuous work without fatigue or breaks so this ability reduces lead times and reduced production costs which is mutually beneficial for manufacturers and end users or consumers of product.

Elimination or minimization of human error by lesser human attention towards the Precision CNC Machining indicates that there will be lesser error consequently the part or product will be more precise, accurate and error free.

Choosing Precision CNC Machining also help to reduce the wastage of valuable material as a result its cost effective as compared to simple CNC Machining because parts produce via Standard/Simple CNC machining are more prone to be rejected if they fail in assemblies hence material along with time and money gets wasted and new block of material is required consequently this is not environment friendly practice.

From tip of Pen to the nozzle of the space rocket almost every consumer good and industrial sector relies on using CNC Machines at some point of their production along with necessity of precision therefore Precision CNC Machining.

Additive Manufacturing is more precise and accurate as the resolution of 3d printers is extremely low some of Stereolithograpy Apparatus SLA printers have positional accuracy of 1 micron which shows they are replacement for standard CNC machines to make complex parts with tight tolerance and accuracy but when it comes to strength, size, build volume, functionality 3d printed parts lack behind so Precision CNC Machining caters for this problem and not only provides high strength parts but can produce complex geometries just like 3d printers.

Chinese manufacturing sector helps to take care of many problems that user face therefore our company by the help of lower labor costs and efficient production we provide Precision CNC Machining services by maintain a tight tolerance of 0.005-0.01mm and where ever necessary if surface treatment required for parts produced with CNC Precision Machining we still be able to achieve a roughness value of less than Ra0.2 which shows we uniquely standout in Chinese’s Manufacturing market.

For further detail and information please contact www.leadmachinery.net or below where our representative will help you to get ease in receiving our unique and cost effective CNC Precision Machining services along with proper guidance and cater for your needs.

Contact Details: No.7 Yuansheng Rd, Yangjian Industrial Park, Wuxi, China

Tel: 86-510-88533858

Fax: 86https://leadmachinery.net/-510-88533858

Cell: +8613961886740

[email protected] Whatsapp: +8615951276160

CNC Machining China: Comprehensive Guide to Services and Manufacturers

Copyright © 2024 SourcifyChina Fabrication | All Rights Reserved.